With all new technologies, adoption is slower than the industry pundits would have you believe. This is certainly true with one of Industry 4.0’s enabling technologies – the Internet of Things (IoT). In the manufacturing world, IoT also known as the Industrial Internet of Things (IIoT). These new technologies promise to shift the paradigm in the industry.

It is daunting knowing that the way we work today is going to change. And it makes sense for manufactures to be cautious until there are proven use cases before making the leap.

That day is here.

Many early adopters are reaping the benefits of smart factories from implementing IIoT technologies. Bain & Company research indicates that the industrial portion of the Internet of Things (IIoT) —including software, hardware and system solutions in the manufacturing, infrastructure, building and utilities sectors—continues to grow rapidly, and could double in size to more than $200 billion by 2021.

We are here to help you navigate on how IIoT will affect the metalworking industry.

What is Industry 4.0 and How is it Connected to IIoT?

Industry 4.0 is more than just a marketing term. Industry 4.0 is a collection of technologies that bring sweeping changes to manufacturing. According to management consulting firm BCG, Industry 4.0 is an evolution that makes it possible to gather and analyze data across machines, enabling faster, more flexible, and more efficient processes to produce higher-quality goods at reduced costs.

During the next decade, digital manufacturing technologies will enable companies to connect physical assets and create a flow of data across the value chain that will link every phase of the product life cycle, from design, sourcing, and production to distribution, point of sale, and the end user.

One of Industry 4.0’s enabling technologies is IIoT. IIoT is a collection of technologies that include sensors, software, networks, cloud computing, and analytics. The combination of these elements make every machine smart.

How Does IIoT Work?

Every IIoT solution includes the following five basic functions:

1. Data Collection

The primary form of data collection is through a sensor. Sensors continually monitor and collect data on energy usage, environmental and operational conditions such as temperature, vibration, time-to-complete, downtime, and more. Sensors will eventually become embedded in CNC machinery and become part of a standard offering.

For companies that want to take advantage of the benefits of IIoT today, replacing all existing machines with sensor-enabled equipment is often not an option. One low-cost alternative is to retrofit machines with external devices that include sensors to make them IIoT-compatible. These devices bolt onto equipment and contain sensors, connectivity, and control.

2. Connectivity

Sensors and retrofit devices connect to a network using hard-wired or wireless connections. Wireless removes the cost and complexity associated with dedicated wiring and allows you to place machines in areas where wiring is limited or too costly to implement.

Common wireless protocols used in IIoT are cellular, WiFi, Near Field Communication (NFC), Zigbee, and Bluetooth (Low Energy). Choosing which protocol to use is dependent on a variety of factors including environment, distance, location, IIoT platform, and more.

3. Edge Computing

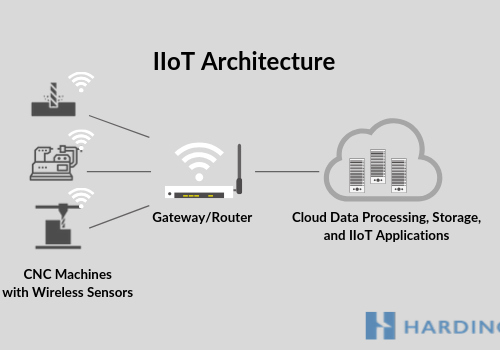

Massive amounts of data are collected from machines and can put a strain on networks. It is much more efficient to pre-process data on a device and send only the data that has value to the cloud for storage. The network manager, also referred to as the gateway or router, is a software and hardware device that sits at the edge of the IIoT network and between the factory and internet/cloud. It is the connection point between the factory and the cloud platform.

The software that controls the network manager/gateway performs several functions. It aggregates and pre-processes data collected from sensors and IIoT devices before sending it to the cloud for storage and for use in IIoT applications. It also receives data and instructions from IIoT applications that are passed back to IIoT devices that can trigger some type of action in machines, such as shutting it down.

4. Cloud Data Processing and Storage

Data needs to be stored for use in IIoT applications. Manufactures use that data to uncover patterns in machine operations. For example, you may learn that every day at 2:00PM there is vibrations in the machinery or there is an unexplained lull in production. Once you learn that, you can uncover the root cause and take action to correct it.

Only cloud computing has the potential to scale quickly as well as store and process the volumes of data that IIoT generates. It is too costly to do on site.

5. IIoT Applications

Applications such as remote monitoring and predictive maintenance analyze the collected data and present the results in a dashboard format. A dashboard is the primary user interface that provides an easy way to understand complex data. It displays key performance indicators (KPIs) such as efficiencies/inefficiencies and other metrics in a graphical or user-friendly way. It presents insight about machine operations to guide future decisions.

Are You Ready?

Now is a good time to learn more about IIoT and understand the investment needed to take advantage of the benefits garnered by implementing smart technologies. The IIoT will increase efficiencies of CNC machines helping to lower wastage and lower costs. It also decreases downtime with predictive maintenance. If efficiencies are increased and downtime reduced, that translates into more profitability for your business.