Today, manufacturing firms face tremendous pressure to adapt to new trends while keeping costs low and optimizing productivity — but it’s not easy. With customer demand for increased customization and shorter lead times, not to mention rising costs and pressures to improve efficiencies, the business of making components gets more complex every day.

Now there’s a new imperative to meet – produce parts and workpieces with detail accuracies not previously attainable with traditional lathes or turning equipment. And produce them accurately and cost-effectively.

In the bearings market as well as vertical industries such as aerospace and transportation, new efficient product designs require extremely complex and tight-tolerance components. After all, workpiece accuracy is vital to meeting critical safety and equipment design standards, as well as ensuring optimal performance of the finished products. But this requirement for very precise workpieces can stretch or even overwhelm the machine tool abilities of some providers.

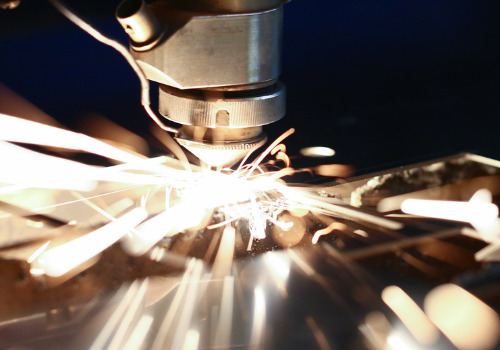

Process automation from modern CNC machining has helped manufacturers produce everything from prototypes to finished fabricated parts with better precision in a shorter period of time. But new specifications of workpieces with extremely tight tolerances can exceed the current capabilities of CNC machine tooling equipment.

In order to turn out perfect parts that meet customers’ exacting tolerances in a repeatable fashion, manufacturers need to rethink normal. Today, grinding machines are used to achieve the precision and accuracy required but it is slow, expensive, and hard to deal with grinding byproducts.

Manufacturers need to rethink their approach to production and what is considered “normal” capabilities for turning centers and lathes. Advanced technology now enables turning instead of grinding to achieve similar accuracy, but in a faster and more cost effective manner.

The importance of precision

In today’s advanced manufacturing space, there’s no room for error. Parts must meet the engineering specs, with no variance — period. To achieve optimal efficiency and parts uniformity, industry leaders use super precise turning centers to produce complex workpieces with painstakingly correct detail and form tolerances. Super precise turning centers incorporate a combination of best practice design and hardware/software integrated into a production machine tool. These machines are able to produce meticulous results with a minimum of human intervention – time and time again.

Super precise turning centers are ideal for intricate items with a high level of detail, delicate part handling, and for parts to be completed in a single setup. Along with the ability to work with a variety of materials, the machines can be pre-configured to produce complex parts in the most effective manner while offering high repeatability accuracy and remarkable finish quality. Better yet, the machine will be able to produce the exact same part to the same specifications, even months or years later, with no variation between production runs.

Size Matters – How precise is “super precise”?

While many machine tools offer standard resolutions of .0001″, the new industry standards require machinery that incorporates .000010″ programmable resolution capabilities, beyond the capabilities of many manufacturers. But modern super-precision turning centers can provide accuracy in the lower range of diamond-turning machines (cylindricity of less than 1–2 μm), turning out pieces within the 2-micron range.

With super precision turning centers, manufacturers can achieve outstanding performances and meet exacting standards up to .5 micron. How small is that? With bacteria cells typically sized at 1 micron, that makes .5 micron only half the width of a single cell.

We’re talking about parts with accuracy at the microscopic level.

Form Tolerances Also Matter

Along with precise details, workpieces need to meet form tolerance standards and the desired geometric form, including roundness and cylindricity. Good news – super precise turning centers shine here as well, producing workpieces with exact surface finish and form tolerances from 2D to 3D accuracy.

Stability – It’s All About the Base

The remarkable accuracy produced by super precise turning centers can only be accomplished with an extremely stable base. Super precise turning centers have to have extraordinary stiffness and unmatched stability to offset the high-pressure force of the machining process. This stability inhibits thermal deformation and twisting, allowing for super precise cutting performance and demanding part accuracies.

The New Normal is Super Precise

With super precise turning centers, you can consistently produce perfect, uniform parts that meet your exact needs and specifications. You can even customize parts to meet special application design standards or unique customer requirements. At Hardinge, we offer industry leading SUPER-PRECISION® turning equipment for a variety of applications. Learn more here.