Often used as part of a lathe or in conjunction with a rotary table on a milling machine, a tailstock is designed to support the free end of a long work piece with a center during machine operations. Does your CNC turning center, grinding or milling machine need a tailstock? The short answer is probably “yes”, if you want to accurately machine long slender piece parts without any distortion or chatter (meaning the workpiece could bend excessively while being cut, compromising quality and perhaps damaging the material or tool).

Industry recommendations state that tailstocks should be used or considered to support any part that exceeds the 3:1 length-to-diameter ratio, in order to maintain accuracy and produce a high-quality finish. The higher the L to D ratio, the greater the risk of deflection and chatter occurring. For example, a work piece with a 1” diameter and 6” length has a 6:1 L to D ratio and needs a tailstock for support.

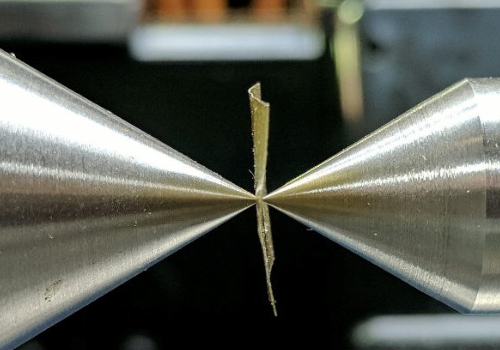

A tailstock enables a CNC machine to precisely and safely process shaft-type work pieces. The tailstock is typically used to support the components via the use of a live center. A live center is a cone shaped object with a Morse taper adapter that’s inserted into the tailstock. The cone portion spins on an internal ball-bearing mechanism. This is used to fit into a center hole of the work piece to hold it firmly between the tailstock and chuck. Thus equipped, the tailstock is able to hold the work piece’s longitudinal rotary axis steady and completely parallel, eliminating distortion.

Another common application for tailstocks is drilling out the centers of work pieces, by holding the cutting tools used to perform hole-making operations like drilling and tapping. Tailstocks can firmly hold the cutting tools (such as drills or reamers), feeding the drill (or other tool) directly into the work piece to cut or make the holes.

Ensuring Part Quality with Tailstocks

But it’s not just long thin parts that can use extra support. Large or heavy work pieces, which could easily become dislodged from the workholding device during heavy machining, also benefit from the increased stability provided by a tailstock. If you have work pieces with short gripping length in the workholding, a tailstock can also prevent these parts from becoming dislodged during machining. Finally, when machining a component that requires multiple diameters with a high degree of concentricity accuracy, a tailstock allows all the diameters to be machined in a single operation.

That said, tailstocks aren’t needed for every job. For example, if you are turning a short piece (less than 3:1 LTD ratio) of material, you can get by without a tailstock. And if you are boring or drilling on a lathe, a tailstock wouldn’t be used. In certain cases, the sub spindle on some CNC lathes can even be utilized as a tailstock. But, in general, having a tailstock on your CNC machine is a vital ingredient for high precision machining.

How does a tailstock work?

Located opposite the headstock on the right side above the lathe bed, the tailstock can accommodate components with different lengths by sliding along the way system to engage the part being worked on. Usually, the entire tailstock is manually moved to the approximate position that will be needed. There, it is locked in place. A leadscrew is used to move the tool mounted onto the tailstock to the exact position where it is needed. When a cutting tool such as a drill bit or reamer is used, the feed is done with the leadscrew.

The standard taper on most lathe tailstocks is a Morse taper mounted to the end of it. With the tailstock quill or extendable portion equipped with a Morse taper, it can secure taper-shank tools such as chucks, drills, reamers, and counterbores.

A variety of tailstocks available

Tailstocks come in a variety of styles depending upon the machine and the manufacturer. Tailstock types include manual body, with a manual or programmable quill, and programmable body with or without a quill. Each have their own advantages and disadvantages. For example, a manual tailstock with programmable quill provides additional support for long or slender machining operations. When a CNC machine is equipped with a programmable tailstock, it can provide simple, precise and automatic control of directional movement and holding pressure to support long, heavy workpieces for consistent high-accuracy turning.

Hardinge Tailstock Options

As a worldwide provider of highly reliable CNC lathes and turning centers, Hardinge produces a selection of rigid and reliable machines equipped with flexible tailstock systems to meet the varied requirements of our customers. For example, our GS-Series turning centers, designed for speed, power, accuracy, and durability, can increase throughput and reduce cycle time in a single setup, thanks to their multitasking abilities. Featuring a robust one-piece cast iron base, heavy-duty linear guideways and ball screws, as well as other value-add features, these versatile machines beat the competition with their fully-programmable #4 MT hydraulic tailstock option that eliminates human intervention. And our newly launched GSi series of lathes include many of the same high-end control features as the GS-Series, but with a compact design and affordable price for small-to-midsize shops and educational facilities.

Ready to benefit from tailstock capabilities? Both GS and GSi series are currently available and in stock for immediate shipment, so notify your Hardinge representative today.