|

|

GS 150 |

GS 200 |

GS 250 |

Spindle HP

Spindle Speed |

24.7 (18.5kw)

6,000 RPM |

24.7 (18.5kw)

5,000 RPM |

35 (26 kw)

3,500 RPM |

|

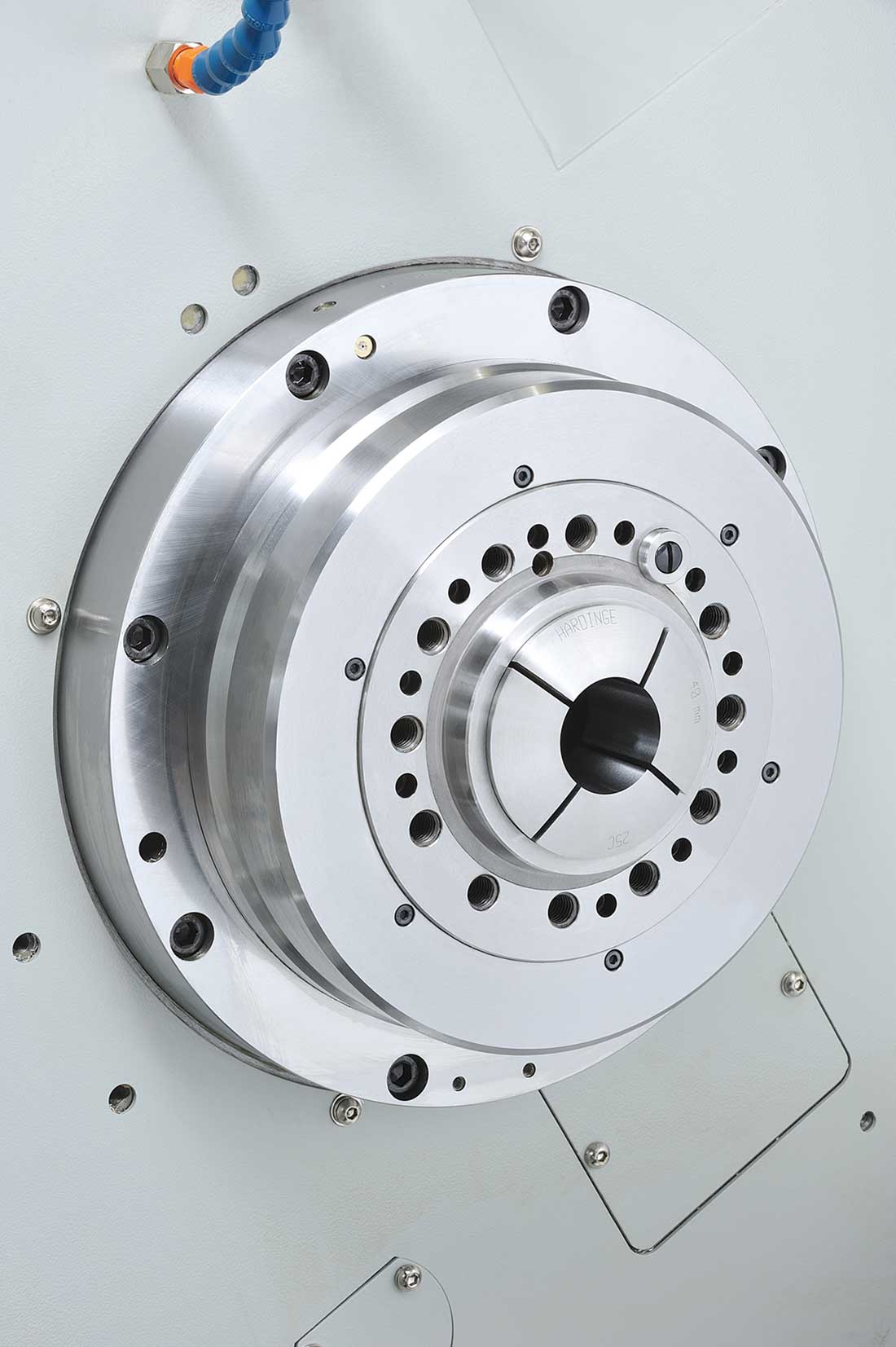

Chuck Size |

6" (150 mm) |

8" (200 mm) |

10.00" (254 mm) |

|

Max. Machining Length |

16" (406 mm) |

16" (406 mm) |

23.62" (600 mm) |

|

Max. Machining Diameter |

11.1" (284 mm) |

11.1" (284 mm) |

14.015" (356 mm) |

|

Bar Size |

1.77" (45 mm) |

2.05" (52 mm) |

3.070" (78 mm) |

|

No. Turret Stations |

12 |

12 |

12 |

|

CNC Control Unit |

FANUC 32 bit OiTF |

FANUC 32 bit OiTF |

FANUC 32 bit OiTF |

|

Approx. Machine Weight |

5,940 lbs (2,694 kg) |

6,160 lbs (2,794 kg) |

11,583 lbs. (5,265 kg) |

|

Floor Space |

78.66" x 61" x 70.12"

(1,998 mm x 1,551 mm x 1,781 mm) |

78.66" x 68"

(1,998 mm x 1,650 mm) |

117.64" x 80.35" x 71.33"

(2,988 mm x 2,041 mm x 1,812 mm) |

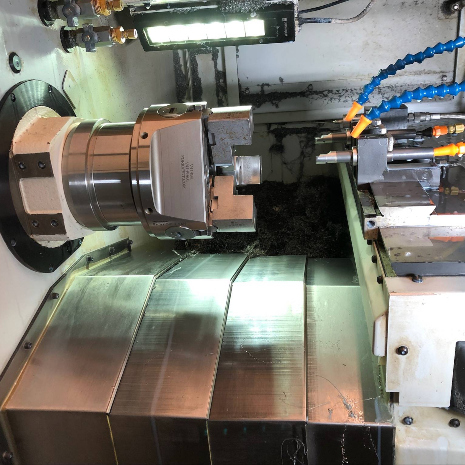

Features

- 3-Jaw wedge-style chuck

- One-degree spindle orient

- Spindle reference (servo lock)

- Rigid tapping

- Run time and parts counter

- Chuck/collet closer foot switch

- Chip conveyor Interface

- Swing-out CNC pendant

- Air hose with air gun

- Complete operator’s, programmer’s and maintenance documentation

Options

- Automatic tool touch probe

- Parts catcher & probe

- 20-Bar (280-psi) thru-tool coolant

- Robust hydraulic

- Thermal Stabilization Package

- Chip conveyor

- Bar feed interface

- Power transformers

- Stack light

- Mist collector

FANUC Oi-TF

- 8.4” Color LCD Display

- Two Interpolating Axes

- Programmable Resolution – 0.001mm (0.0001”)

- Tool Offset Capability – 0.001mm (0.0001”)

- Tool Geometry and Tool Wear Offsets

(64 pair each)

- Inch/Metric Data Selection by G-Code

- 1280 Meters (512 KB) Part Program Storage

- Flash Card Slot Capability (up to 128 MB)

Conversational programming features offered on the CNC control is the CNC control builder’s standard product, which may not fully support all machine functions. It is recommended the end user reference the control system documentation, or contact the control manufacturer, for further details of use or customization.

.jpg)

-150x150.jpg)