|

|

GS150i |

GS200i |

|

Coolant Facilities |

|

|

|

Reservoir Capacity |

125L |

125L |

|

Pump Size |

1.1HP |

1.1HP |

|

Pumo Rating |

26L |

26L |

|

Pressure |

30psi (2Bar) |

30psi (2Bar) |

|

Turret/Top Plate (Standard) |

|

|

|

Type |

Motor Drive Turret |

Motor Drive Turret |

|

Number of Stations |

12 |

8 |

|

Top Plate Size Across Flat |

11.26” (286mm) |

11.02” (280mm) |

|

Index Time Next Station (Unlock, Index, & Lock) 45 |

0.45 sec |

0.45 sec |

|

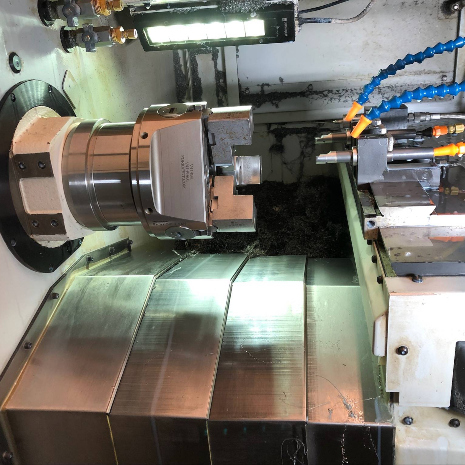

Chuck |

6” |

8” |

|

Max Speed |

6000rpm |

5000rpm |

|

Stroke |

0.5” (12mm) |

0.63” (16mm) |

|

Jaw Movement |

0.108” (2.75mm) |

0.29” (7.4mm) |

|

Thru Hole |

1.77” (45mm) |

2.05” (52mm) |

|

External Chucking Capacity |

0.51”-6.5” (13mm-169mm) |

0.51”-8.26” (13mm-210mm) |

|

CNC Control (Standard) |

Fanuc 0i TF 8.4“LCD |

Fanuc 0i TF 8.4“LCD |

Main Features:

- Feature packed, industry leading FANUC control system

- Environmentally friendly automatic grease lubrication system

- Proven machine structure based on the existing Hardinge GS150 turning centers

- Compact footprint, smallest in class

- Full cast iron 45° base construction

- Fast Spindle speeds up to 5,000 RPM on GS 200i and 6,000 RPM on GS 150i

- Rigid Structure

- One piece bed and base structure

- Heavy Duty 2-Row Linear Guideway

- High Precision and High Stifness Spindle

- X and Z Axis Travels

Fanuc 0iTF

- 8.4″ Color LCD Display

- Two Interpolating Axis

- Programmable Resolution – .0001″/.001mm

- Tool Offset Capability – .0001″/.001mm

- Tool Geometry and Tool Wear Offsets (64 pair each)

- Inch/Metric Data Selection by G-Code

- 1280 Meters (512KB) Part Program Storage

- Flash Care Slot Capability (up to 128 MB)

For more please download the brochure below.

Conversational programming features offered on the CNC control is the CNC control builder’s standard product, which may not fully support all machine functions. It is recommended the end user reference the control system documentation, or contact the control manufacturer, for further details of use or customization.