|

|

|

|

|

Main specifications |

|

metric |

|

Distance between centres |

mm |

600 / 1'000 |

|

Centre height |

mm |

200 |

|

Weight of workpiece between centres |

kg |

100 / 150 |

|

Load on chucked work |

Nm |

100 / 200 |

|

Mains voltage required |

V |

3 x 380V/50 Hz / 3 x 460V/60Hz |

|

Power consumption depending on equipment |

A |

35-63 |

|

Space required / length x width |

mm |

2620 x 2170 / 3400 x 2170 |

|

Longitudinal slide: Z-axis |

|

|

|

Travel |

mm |

750/1150 |

|

Rapid traverse speed |

m/min |

20 |

|

Resolution |

µm |

0.1 |

|

Wheelslide: X-axis |

|

|

|

Travel |

mm |

365 |

|

Rapid traverse speed |

m/min |

10 |

|

Resolution |

µm |

0.1 |

|

Swivel devices |

|

|

|

Swiveling range |

° |

280 |

|

Automatic indexing |

° |

1 |

|

Resolution B-axis |

° |

0.1 seconds |

|

Wheelhead general |

|

|

|

Oil-air lubracation spindle |

kW |

11.5 |

|

Wheel constant speed |

m/s |

50 / 63 (option) |

|

Max. wheel diameter |

mm |

Ø 500 |

|

Internal grinding attachment |

|

|

|

Bore for spindles up to |

mm |

Ø 150 |

|

Internal grinding wheel power |

kW |

7.5 - 15 |

|

Oil-Air lubricated grinding spindle max, speed |

min-1 |

45'000 / 60'000 / 90'000 |

|

Workhead 100 / 150 |

|

|

|

Resolution C-Axis |

° |

until 0.00003 |

|

Rotation spindle speed |

min-1 |

1 - 1'000 |

|

Drive torke |

Nm |

until 63 |

|

Interface |

|

MT5/ISO702-1, size 5 |

|

Roundness accuracy in chucked work |

µm |

until 0.2 |

|

Tailstock |

|

|

|

Internal taper |

|

MT4 |

|

Retraction of sleeve |

mm |

49 |

|

Micro-adjustment |

µm |

±30 / ±75 |

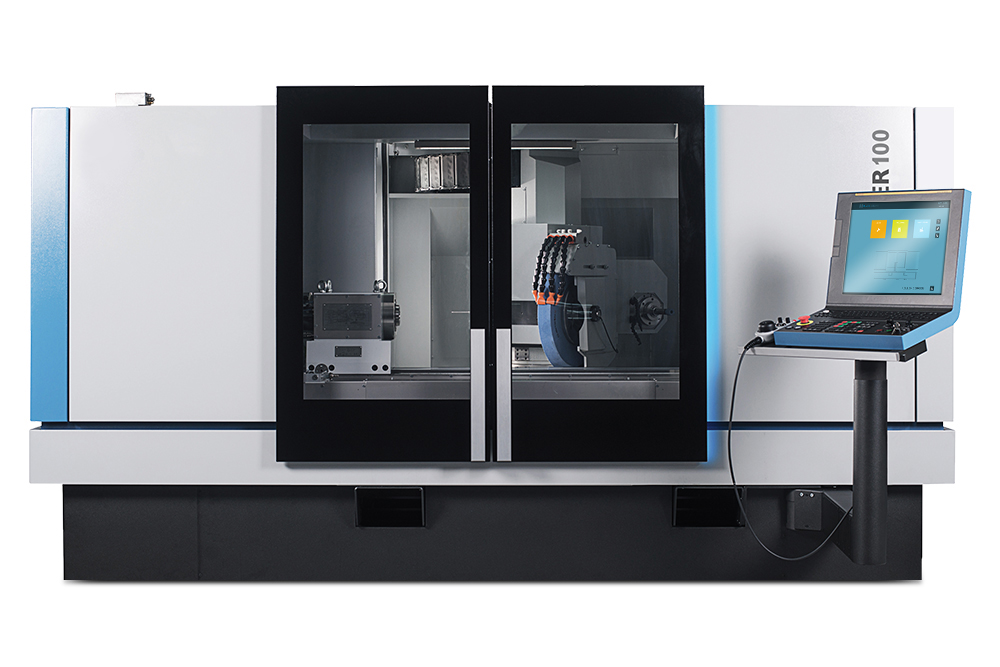

The KELLENBERGER 100 grinding machine features an aesthetically and ergonomically advanced design; its clean and modern appearance relays its perfection and technical superiority in accordance with the other members of the KELLENBERGER family of grinding machines. The innovation of a new grinding wheel head offers a choice of 10 versions, along with increased power.

Powered by FANUC® 31i, the KELLENBERGER’s new, high-resolution 19″ industry-leading touchscreen control system is equipped with onboard BLUE Solution “teach-programming,” along with an OBJECT Guide feature that reduces the barrier of entry for machinists, maximizes automation, and allows for guided and simple program creation. The user interface was developed explicitly for grinding applications by KELLENBERGER’s world-class engineers in conjunction with customer input with the intent to facilitate any user regardless of the individual’s level of machining experience. Drawing inspiration from the skeuomorphic design philosophy, object-driven guides, onboard tutorials, intuitive operation, and AI-driven machine suggestions for parameter improvements, the KELLENBERGER 100 can be operated without any prior ISO programming skills.

The innovative BLUE Solution greatly reduces training costs, minimizes waste, allows for safer operation, increases machine uptime, and further drives automation. The optional RED Solution enables the user to directly import DXF files, automatically generates technical data, and offers a visual representation of the current grinding wheel position. An auxiliary handheld panel gives the user quick access to crucial axis and speed selection switches. The cutting-edge operating system interfaces with Microsoft® Windows™ machines for full Industry 4.0/IoT integration to facilitate a future of complete manufacturing automation.

As CNC grinding requirements grow increasingly more complex, only world-class grinding machines will suffice. As manufacturing demands continue to evolve at a rapid pace, solutions optimized for machine learning and automation are of paramount importance. For the next generation of precision universal OD/ID CNC grinding and manufacturing, customers can count on the KELLENBERGER 100 universal grinding machine to rise to every occasion and do so while yielding significant cost savings, reduced machine downtime, optimized automation, and even greater precision.

- Global innovation of a new grinding wheelhead with choice of 10 wheelhead versions

- optimised design of the machine

- Higher power of the grinding wheel

- Increased productivity

- Redesigned Z-guideways

- Greater profile accuracy

- C-axis with direct drive

- Increased accuracy for noncircular grinding

- Extended options available as standard

- High-quality Fanuc 31i control

- Integrated automatic technology calculation

- Intuitive touchscreen operation

- Extended range of functions

- More grinding options

- Consistent operator guidance

- Simple and convenient training

FANUC control system 31i-B

- FANUC 31i-B with 19” touch display

- Intuitive operation thanks to

BLUE Solution with Object Guide

- Clear, self-explanatory screen pages

- Integrated automatic calculation of technology

- Capto

- OD Production Grinding

- Universal ID/OD Cylindrical Grinding