|

|

|

|

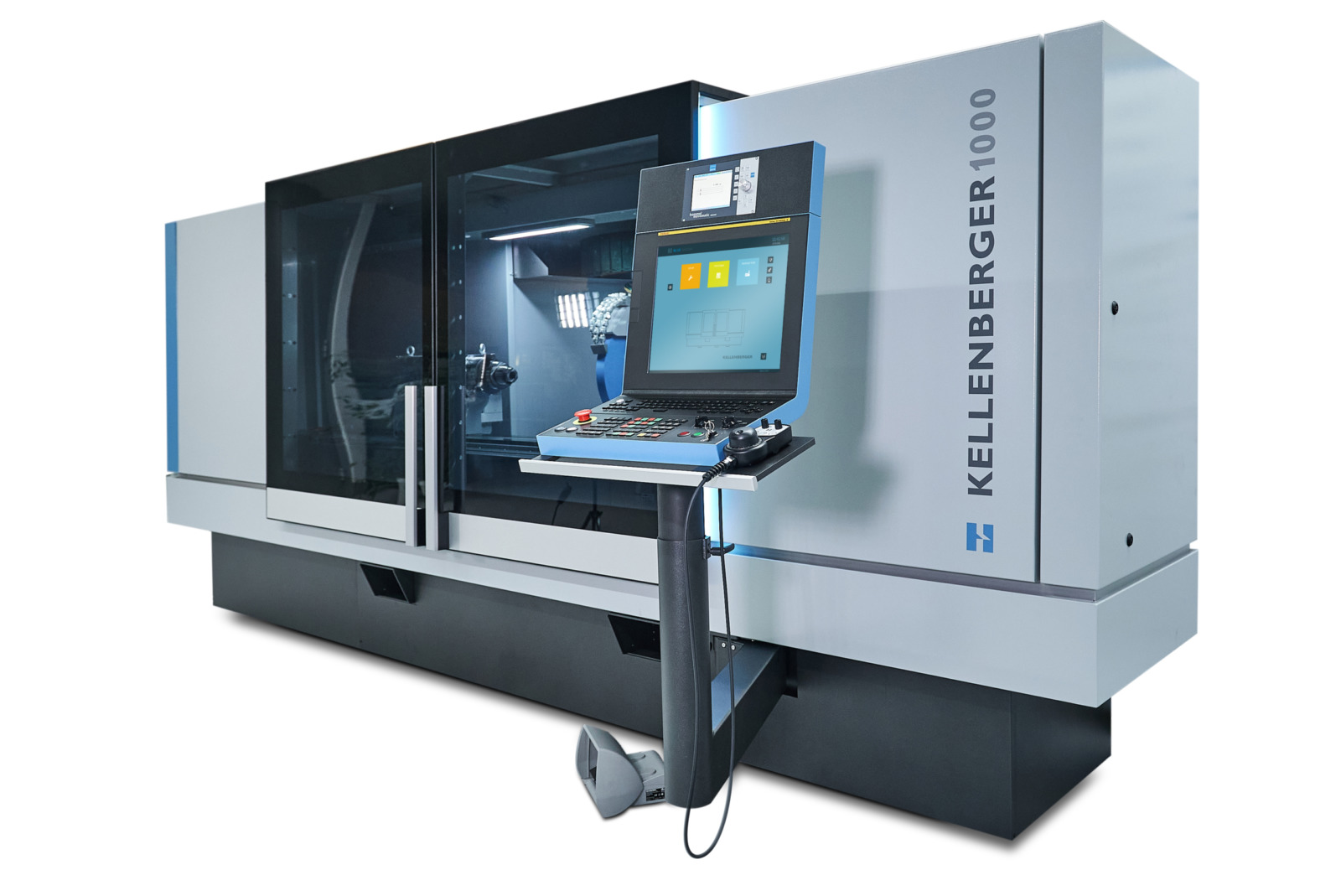

Kellenberger 1000 |

|

|

|

metric |

imperial |

|

|

|

Main specifications |

|

|

|

|

|

Distance between centres |

mm |

inch |

1000 / 1600 |

40 / 63 |

|

Grinding length |

mm |

inch |

1000 / 1500 |

40 / 59 |

|

Centre height |

mm |

inch |

200 / 250 / 300 |

7.87 / 9.84 / 11.81 |

|

Weight of workpiece between centres |

kg |

lbs |

150 / 200 / 300 |

330 / 441 / 660 |

|

Load on chucked work |

Nm |

lbft |

160 / 320 / 750 |

118 / 236 / 553 |

|

Mains voltage required |

|

|

3 x 400 V / 50 Hz / 3 x 460 V / 60 Hz |

3 x 400 V / 50 Hz / 3 x 460 V / 60 Hz |

|

Power consumption depending on equipment |

A |

A |

35-63 |

35-63 |

|

Space required / length x width |

mm |

inch |

3600 x 2050 / 4600 x 2050 |

141.73 x 80.70 / 181.10 x 80.70 |

|

Longitudinal slide: Z-axis |

|

|

|

|

|

Travel |

mm |

inch |

1170 / 1670 |

46.06 / 65.74 |

|

Rapid traverse speed |

m/min |

ipm |

20 |

787 |

|

Resolution |

µm |

µinch |

0.1 |

0.004 |

|

Wheelslide: X-axis |

|

|

|

|

|

Travel |

mm |

inch |

365 |

14.37 |

|

Rapid traverse speed |

m/min |

ipm |

10 |

393 |

|

Resolution |

µm |

µinch |

0.1 |

0.004 |

|

B-axis |

|

|

|

|

|

Resolution |

° |

° |

0.00002° |

0.00002° |

|

Swiveling range |

° |

° |

max. 240 |

max. 241 |

|

Wheelhead general |

|

|

|

|

|

Drive motor water-cooled |

kW |

hp |

10 |

13.4 |

|

Peripheral grinding wheel speed |

m/s |

ft/min |

max: 45 |

max: 8860 |

|

Wheelhead Universal |

|

|

|

|

|

Grinding wheel dimensions, lefthand side |

mm |

inch |

400 / 500 |

16 / 20 |

|

Grinding wheel dimensions, righthand side |

mm |

inch |

300 / 400 / 500 |

12 / 16 / 20 |

|

Wheelhead Tandem-type |

|

|

|

|

|

Grinding wheel dimensions, lefthand side |

mm |

inch |

400 / 500 |

16 / 20 |

|

Grinding wheel dimensions, righthand side |

mm |

inch |

400 / 500 |

16 / 20 |

|

|

|

|

|

|

|

Wheelhead Diagonal |

|

|

|

|

|

Grinding wheel dimensions, lefthand side |

mm |

inch |

400 / 500 |

16 / 20 |

|

Grinding wheel dimensions, righthand side |

mm |

inch |

400 / 500 |

16 / 20 |

|

|

|

|

|

|

|

Internal grinding attachment |

|

|

|

|

|

Bore for spindles up to |

mm |

inch |

120 |

4.72 |

|

HF spindles MFM |

rpm |

hp |

10 / 15 |

13.4 / 20.1 |

|

Rotational speed 1224 / 42 |

min-1 |

rpm |

42‘000 |

42‘000 |

|

Rotational speed 1242 / 60 |

min-1 |

rpm |

60‘000 |

60‘000 |

|

Workhead Standard / Direct drive 200 / Direct drive 300 |

|

|

|

|

|

Rotational spindle speed |

min-1 |

rpm |

1-1000 / 1-1000 / 1-500 |

1-1000 / 1-1000 / 1-500 |

|

Internal taper |

|

|

MT5 / MT5 / MT6 |

MT5 / MT5 / MT6 |

|

Short taper holder, outside |

° |

° |

ISO 702-1: Size 5 / Size 5 / Size 8 |

ISO 702-1: Size 5 / Size 5 / Size 8 |

|

Micro-adjustment |

sec |

sec |

±60 |

±60 |

|

Tailstock |

|

|

|

|

|

Internal taper |

|

|

MT4 |

MT4 |

|

Retraction of sleeve |

mm |

inch |

49 optional 79 |

1.96 optional 3.15 |

|

Micro-adjustment |

µm |

µinch |

± 1.5' |

±6 |

|

CNC control system |

|

|

|

|

|

Heidenhain |

|

|

GRINDplus 640 |

GRINDplus 641 |

|

FANUC |

|

|

Fanuc 31i |

Fanuc 31i |

|

Measuring systems |

|

|

|

|

|

Gap Control |

|

|

KEL-TOUCH |

|

|

Balancing |

|

|

KEL-BALANCE |

|

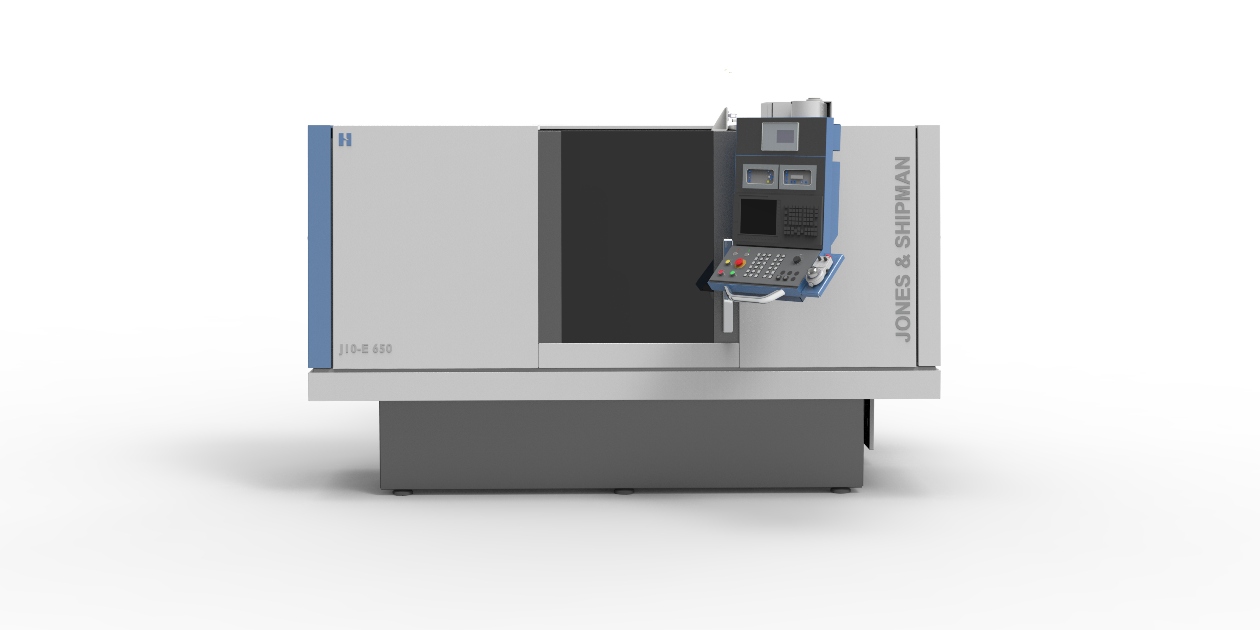

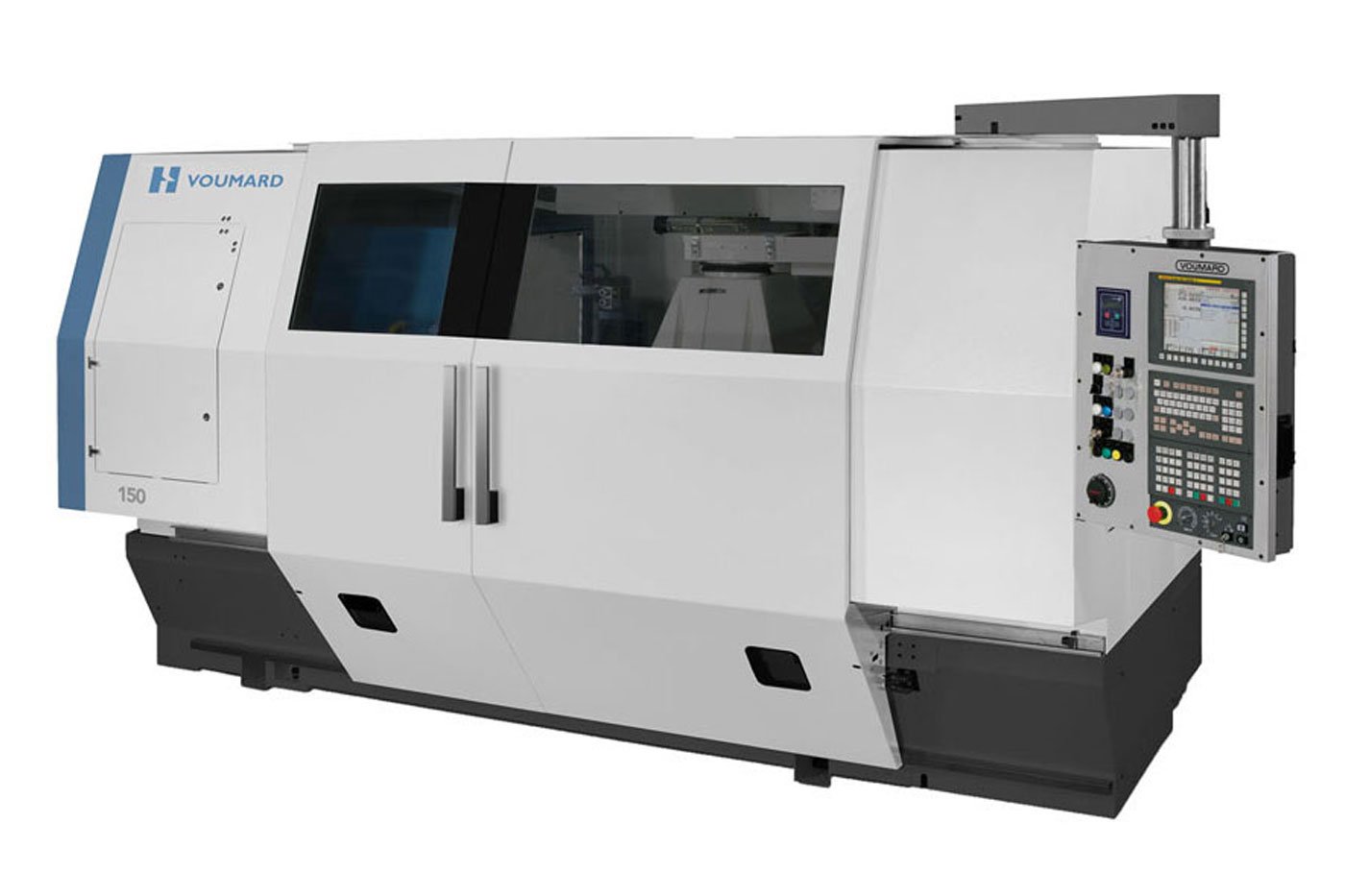

Among the most advanced universal CNC OD/ID grinders in the world, the KELLENBERGER 1000 is designed to deliver the most efficient and capable production functionality available.

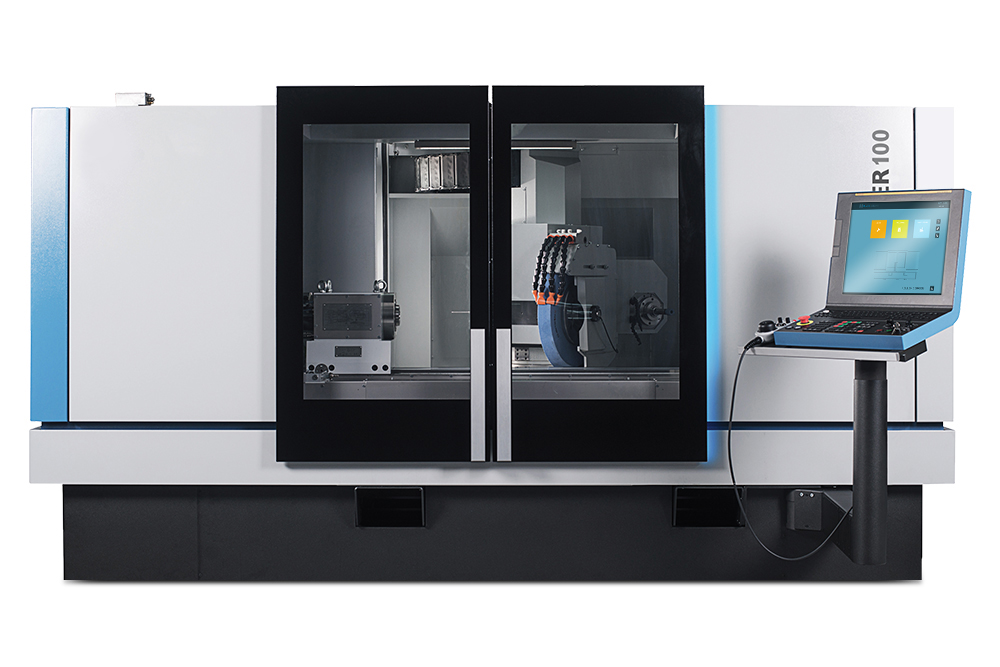

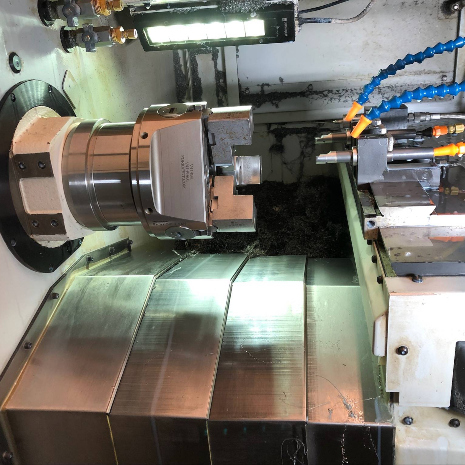

The ergonomics of the KELLENBERGER 1000 grinder allow for maximum visibility of the grinding process through premium laminated safety glass. The machine is centrally arranged and every interface is optimized for complete user control, input, and comfort. The KELLENBERGER 1000 grinding machine is housed in a fully enclosed, three millimeter-thick case that facilitates internal grinding wheels of up to Ø 125 mm.

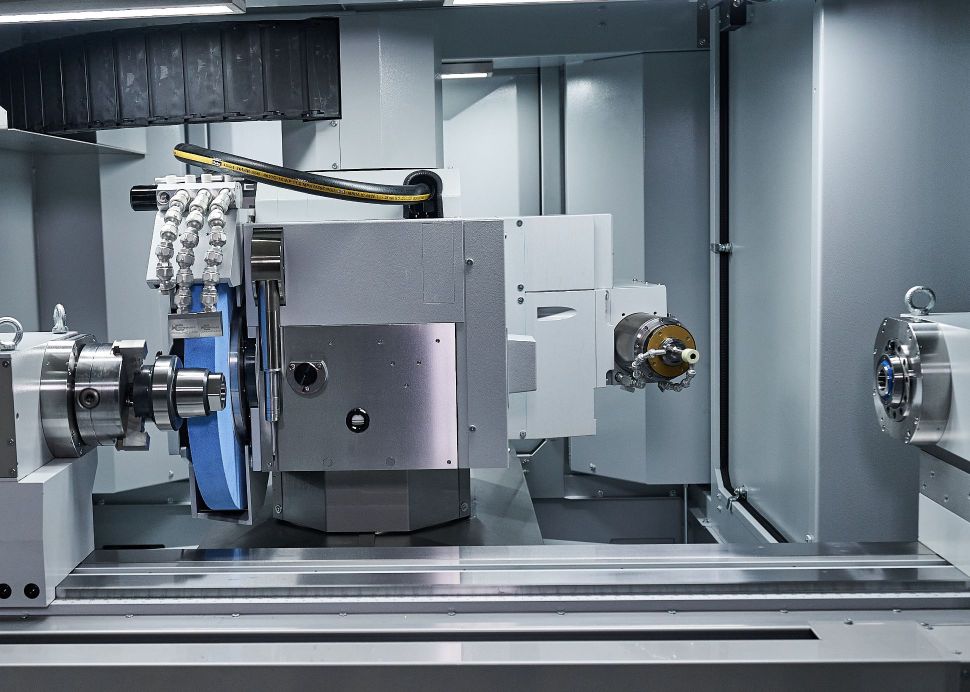

Boasting discreet, practically frictionless hydrostatic guideways with accuracy exceeding millionths of an inch, the Kellenberger® 1000 grinder is built on a new, modular platform concept which redefines universal OD/ID grinding. A fully integrated five-axis control architecture and a redesigned, extended machine table accommodates optimal positioning of the grinding wheel as well as a longer travel distance while simultaneously enabling new machining options and application-specific configurations. Thanks to proprietary design solutions, the KELLENBERGER 1000 grinding machine achieves industry-leading static and dynamic rigidity that effectively eliminates prerequisites for the building foundation on which the machine is placed, and allows for adjustments in increments of 0.1 microns (μm) to be made possible with ease. An extremely stable cast-iron base independent of the machine itself is the most effective foundation for the new platform concept; it facilitates the best thermal stability while acting as a passive vibration dampener to achieve the highest accuracy possible. A sophisticated thermal and energy management system maintains optimal temperatures for all components, including machine hydrostatics, the wheelhead, the high-torque drives, internal grinding spindles, and the electrical cabinet. To further increase universal ID/OD capabilities, the KELLENBERGER 1000 machine can be outfitted with a high-pressure coolant system capable of output up to 10 bars, an interface for a fire extinguishing system, automatic door drives, and a replacement aid for grinding wheels and the tailstock.

For the most demanding CNC grinding requirements, only the very best solutions will suffice. As manufacturing demands continue to evolve at a rapid pace, solutions optimized for machine learning and automation are of paramount importance. For the next generation of precision universal OD/ID CNC grinding and manufacturing, the KELLENBERGER 1000 grinding machine continues to rise to every occasion and does so while yielding significant cost savings, reduced machine downtime, optimized automation, and even greater precision.

The new KELLENBERGER 1000 universal ID/OD grinding machine combines functional design with high-precision technology. Hydrostatic guides guarantee maximum dimensional accuracy in grinding tasks with interpolating axes.

High positioning speeds and accuracies are assured by direct drives for the rotary axes. Generous X and Z axes strokes in combination with the platform concept for grinding head positions and dressing systems ensure universality and allow application-specific configurations.

The proven integral transportation concept (hook machine) has been retained and reduces machine commissioning times and ensures a compact installation area. Durable hydrostatic guides and energy-efficient concepts guarantee a highly secure capital investment.

The following may be added to the KELLENBERGER 1000 for further increased manufacturing capacity:

- Increased coolant pressure up to 10 bar

- Interface for fire extinguisher system

- Automatic door drive

- Replacement aid for grinding wheels and tailstock

FANUC control system 31i

A large 19″ TFT touchscreen display is the gateway to the highly advanced FANUC® 31i control system. Allowing for graphic programming, the ability to import DXF files, storage for up to 99 individual grinding wheels, a readout of expanded process data, program testing with active collision monitoring, and more, the KELLENBERGER 1000 grinding machine’s Windows-embedded, Profibus DP-equipped control system is among the most sophisticated in the world. Specifically designed to handle extremely complex grinding tasks, onboard KEL-GRAPH software automatically generates technical data and allows users to program the Kellenberger® 1000 grinding machine in new, previously impossible ways, further bolstering KELLENBERGER as the industry leader in process automation and Industry 4.0/IoT integration. Self-correcting systems, high-resolution vision systems, tool laser measuring technologies, machine learning, high-resolution probing and measurement systems for automated machining, multi-spindle technology on one platform, an integrated 20 position tool changer for the automatic tool change spindle (ATC), flexible wheel dressing with a rotary dresser attached to the workhead axis, and onboard machine diagnostics are just some of the next-generation, industry-leading capabilities made possible by the KELLENBERGER 1000’s extremely sophisticated control interface designed specifically for a new era of advanced OD/ID CNC grinding.

Wafer production in the semiconductor industry, capto grinding, OD production grinding, universal ID/OD cylindrical grinding, high-tolerance advanced defense manufacturing, next-generation aerospace engineering, and life-saving advancements in the medical industry are just some of the countless applications in which the KELLENBERGER 1000 grinding machine facilitates in large-scale production manufacturing and continued innovation.