|

|

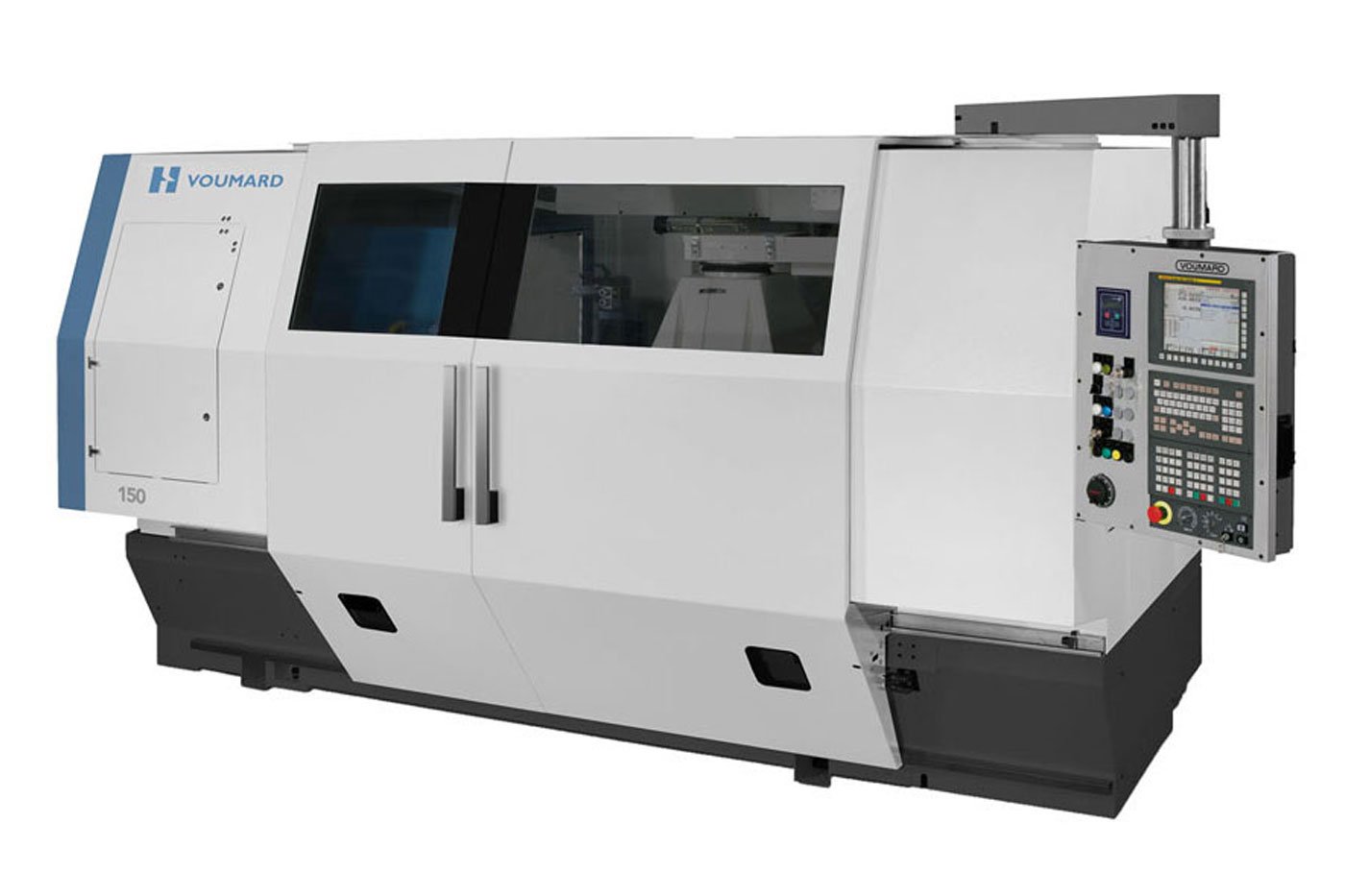

Voumard 150 |

|

Grinding capacities |

|

|

internal diameter, up to max. |

200 mm + grinding wheel Ø |

|

external diameter |

260 mm - grinding wheel Ø |

|

max. recommended depth |

250 mm |

|

Chuck max. dimensions (swing diameter) |

|

|

a) in standard splash guard |

380 mm |

|

b) over workhead table |

350 mm |

|

c) in the gap |

500 mm |

|

Chucking equipment |

|

|

programmable rotation speed |

0 ÷ 850 min-1 oder 560 min-1 |

|

max. compounded weight |

200 or 250 daN/100 mm |

|

axial clamping force |

750 or 1200 daN |

|

X and Z axes |

|

|

useable X travel |

230 mm |

|

useable Z travel |

500 mm |

|

resolution |

0,1 μm |

|

max. traverse speed |

X = 10 m⋅min-1 / Z = 20 m⋅min-1 |

|

Centre height |

|

|

over workhead table |

200 mm |

|

Weight |

5000 to 6000 kg |

VOUMARD 150: the ideal universal ID/OD grinding tool for medium- to large-sized work pieces. The VOUMARD 150 is a multi-purpose tool for ID/OD grinding operations with medium to large sized work pieces in small batches as well as in volume production. While short work pieces can be ground directly when clamped in the chuck, a variety of manual and automatic steady rests is available for grinding operations with long shafts.

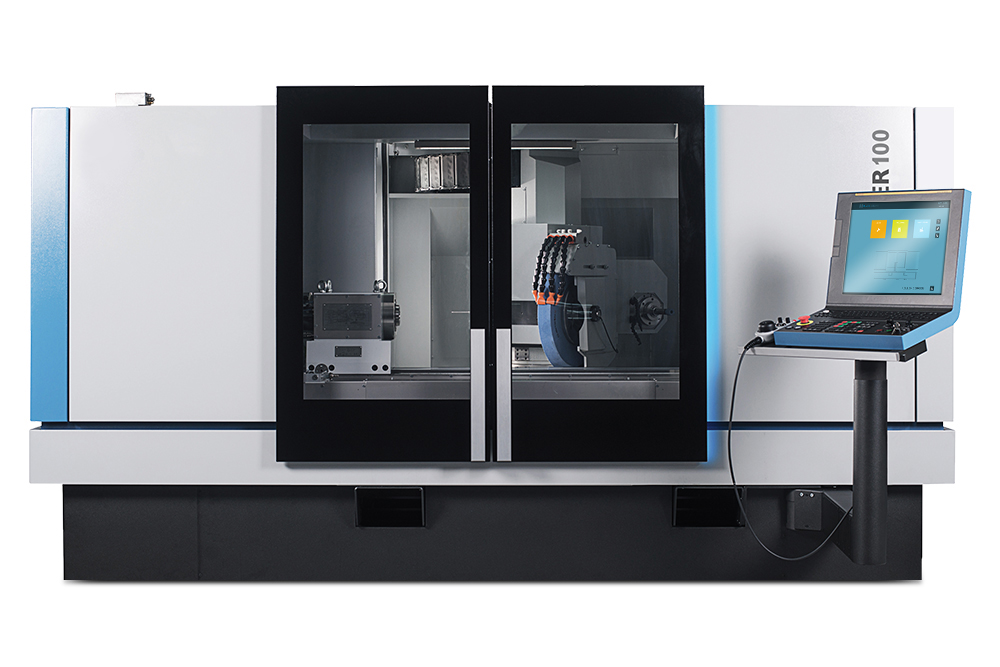

VOUMARD high productivity grinding machines are de- signed for flexible ID and OD grinding operations. Highly accurate chucks and centerless work holding solutions allow for processing work pieces of almost every geom- etry and performing multiple internal and external grind- ing operations in a single clamping.

The VOUMARD machine range provides every cus- tomer with both high productivity and high flexibility grinding solutions. Our machines are appreciated worldwide.

All informations contained in this document are subject to change without notice

wide and integrated in production lines or manufacturing workshops of market-leading companies in major indus- try segments like automotive, aerospace, bearing, tooling and spindle manufacturing.

VOUMARD systems are suitable for a large variety of parts manufactured in large batches (like diesel common rail and hydraulics-pneumatics components) or low quan- tities (like high precision bearings and machines spindles components).

Equipment:

- Four position NC indexing spindle turret (for maximum flexibility) or single spindle stock with two parallel spindels (for highest throughput) permits multiple ID / OD grinding operations with different grinding wheels on the same work piece

- High precision X- and Z-axis

- Manual or numerical controlled B-axis for angular swivel of the workhead for taper grinding

- Work head available for either chuck workholding or with devices for centerless grinding

- Various dressing tools for conventional and CBN grinding wheels

Loading / unloading options

- Manual loading / unloading

- Automatic loading / unloading with double arm device

- Gantry loader

- Robot

- Hydraulic components

- Bearings

- Fuel injection systems

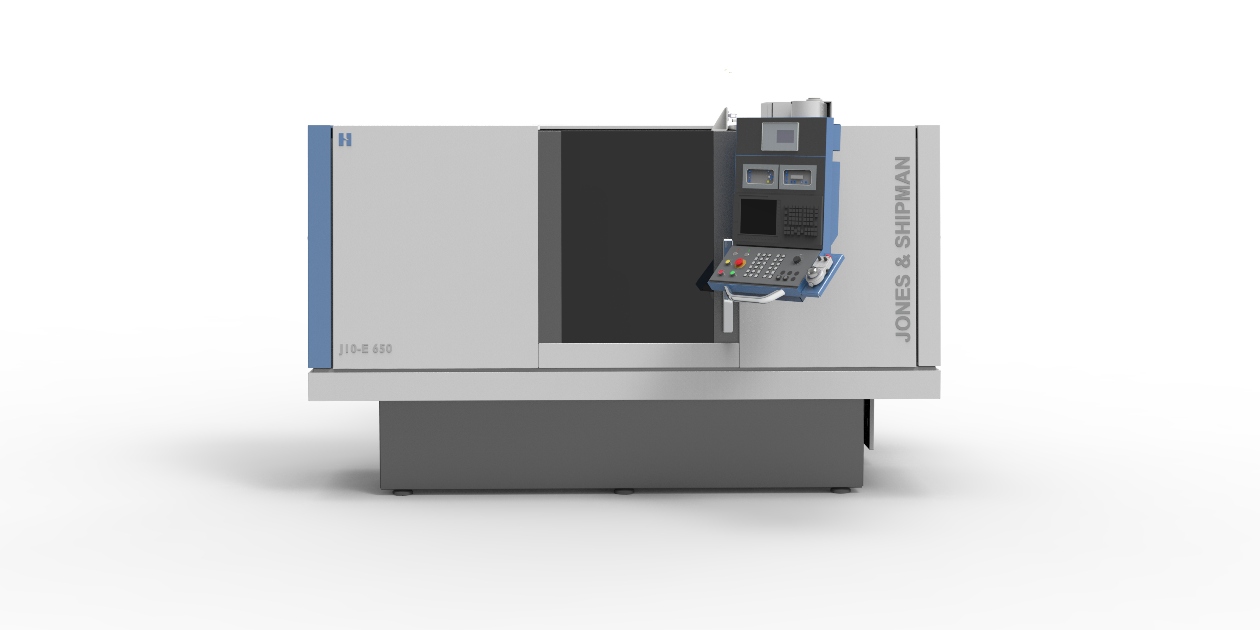

FANUC CNC control with proprietary VOUMARD graphical user interface

Offline programming tool on external computer mini- mizes downtime when creating new grinding sequences

Remote diagnosis system for quick trouble shooting