|

|

GX 300 |

GX 480 |

GX 510 |

GX 710 |

GX 1300 |

GX 1600 |

|

Spindle HP |

20 HP (15kW) |

7.5/10/20 HP (5.5/7.5/15 kW) |

20 HP (15kW) |

7.5/10/20 HP (5.5/7.5/15 kW) |

20/25/34.8 HP (15/18.5/26 kW) |

20/25/34.8 HP (15/18.5/26 kW) |

|

Spindle Speed |

7,083 RPM (Optional 10,000) |

10,000 RPM |

7,083 RPM (10,000 Option) |

10,000 RPM |

12,000 RPM |

10,000 RPM |

|

Travels: X,Y,Z |

11.80" x 15.76" x 16.94"

(300 mm x 400 mm x 430 mm) |

11.80" x 15.76" x 16.94"

(300 mm x 400 mm x 430 mm) |

20" x 15.8" x 16.9"

(510 mm x 400 mm x 430 mm) |

27.95" x 15.75" x 16.93"

(710 mm x 400 mm x 430 mm) |

51.8" x 27.55" x 25"

(1,300 mm x 700 mm x 635 mm) |

62.99" x 27.55" x 25"

(1,600 mm x 700 mm x 635 mm) |

|

Working Surface |

23.6" x 15.8"

(599.44 mm x 401.32 mm) |

23.6" x 15.8"

(600 mm x 400 mm) |

23.6" x 15.8"

(600 mm x 400 mm) |

31.5" x 15.8"

(800 mm x 400 mm) |

56" x 27.5"

(1,425 mm x 700 mm) |

66.93" x 27.55"

(1,700 mm x 700 mm) |

|

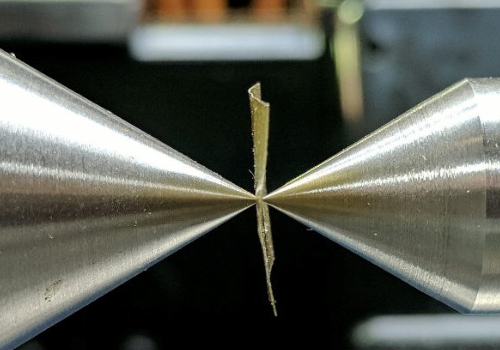

Spindle Taper |

No. 40 BIG-PLUS |

No. 40 BIG-PLUS |

No. 40 BIG-PLUS |

No. 40 BIG-PLUS |

No. 40 BIG-PLUS |

No. 40 BIG-PLUS |

|

Tool Changer |

20 Tools |

20 Tools |

20 Tools |

20 Tools |

30 Tools (40 Optional) |

30 Tools (40 Optional) |

|

Control Type |

FANUC OiMD |

FANUC i-Series GX |

FANUC OiMD |

FANUC i-Series GX |

FANUC i-Series GX |

FANUC i-Series GX |

|

Approx Machine Weight |

10,913 lbs (4,950 kg) |

6,204 lbs (2,820 kg) |

11,244 lbs (5,100 kg) |

6,460 lbs (2,930 kg) |

20,680 lbs (9,400 kg) |

21,560 lbs (9,800 kg) |

|

Floor Space |

57.09" x 100.87" x 93.35"

(1,450 mm x 2,562 mm x 2,371 mm) |

62.01" x 83.35"

(1,575mm x 2,168mm) |

60.04" x 100.87" x 93.35"

(1,525 mm x 2,562 mm x 2,371 mm) |

80.12" x 83.35" x 82.20"

(2,035 mm x 2,168 mm x 2,088 mm) |

129.84" x 108.43" x 113.31"

(3,298 mm x 2,754 mm x 2,878 mm) |

153.4" x 108.43" x 113.31"

(3,898 mm x 2,754 mm x 2,878 mm) |

Bridgeport GX Series vertical machining centers with thousands installed worldwide. These machines include superior design characteristics to ensure many years of accurate and reliable performance.

- Standard 30-tool swing arm

- Optional 40-tool swing arm

- Automatic tool changer (ATC)

- Finite Element Analysis (FEA)

- Stiff and thermally-stable spindle

- Optional tool probe

- 2-Speed Gearbox, Planetary-type

- Swing Arm Type ATC 32-Tools

GX 1300, GX 1600

- Coolant Through Spindle

- Automatic Tool Probe

CNC CONTROLS

FANUC 0i-MD

- 10.4” Color LCD

- AI Contour Control

- Manual Guide i (manual guide Oi

- Max Controlled axes 5

- Simultaneous controlled axes 4

- DNC operation with memory card

- Program restart

- Dry run

- Fine Acc & Dec control

- Least input increment

0.001mm, 0.001deg.

- Servo control HRV3

- Backlash compensation

- Linear interpolation

- Chamfering and corner rounding

- Coordinate system rotation

- Scaling

- Cylindrical interpolation

- Helical interpolation

(Circular interpolation plus Max. 2axes linear interpolation)

- Polar coordinate command

- Circular interpolation

(Multi-quadrant is possible)

- Programmable mirror image

- Background editing

- Extended editing

- Dynamic graphic display

Controller Options

-

- SIEMENS 828D

- Heidenhain ITNC 530 (GX 1300, GX 1600)

Conversational programming features offered on the CNC control is the CNC control builder’s standard product, which may not fully support all machine functions. It is recommended the end user reference the control system documentation, or contact the control manufacturer, for further details of use or customization.

GX-Series Vertical Machining Centers can be found serving a wide array of industries, including:

- Tool & die

- Aerospace

- Pharmaceutical

- Automotive

- Large job shops & OEM