|

|

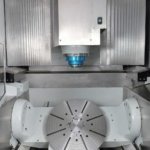

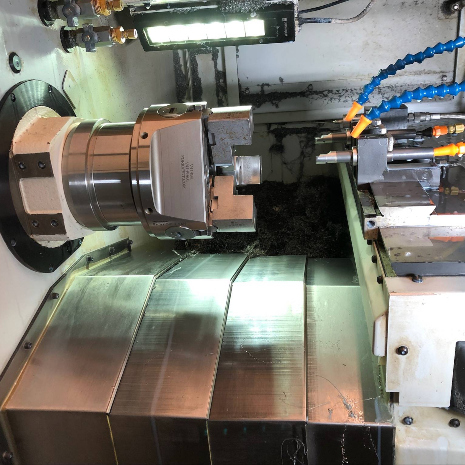

XT 630 5 AX |

|

Spindle (DDS) |

|

|

Taper |

Nr. 40 |

|

Spindle Speed (max) |

15.000 RPM |

|

Horsepower (S1 continuous/S6 40 %) |

10 / 14 kW |

|

Travels |

|

|

X-/Y-/Z-Axis |

762 mm / 630 mm/ 610 mm |

|

Rotation A-Axis (Tilt) |

+30° ~ -120° |

|

Rotation C-Axis (Rotary) |

360° |

|

Spindle (DDS) |

|

|

Table Diameter Size |

Ø 630 mm |

|

max. Work Piece Range (u00d8 x Height) |

Ø 900 x 340 mm |

|

Load Capacity |

350 kg |

|

Automatic Tool Changer |

|

|

Tool Type |

BT 40 |

|

Tool Capacity |

24 |

|

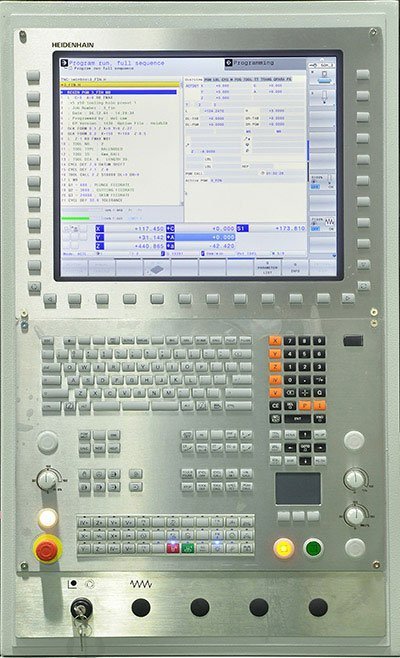

CNC Control |

Heidenhain ITNC 640 FS |

|

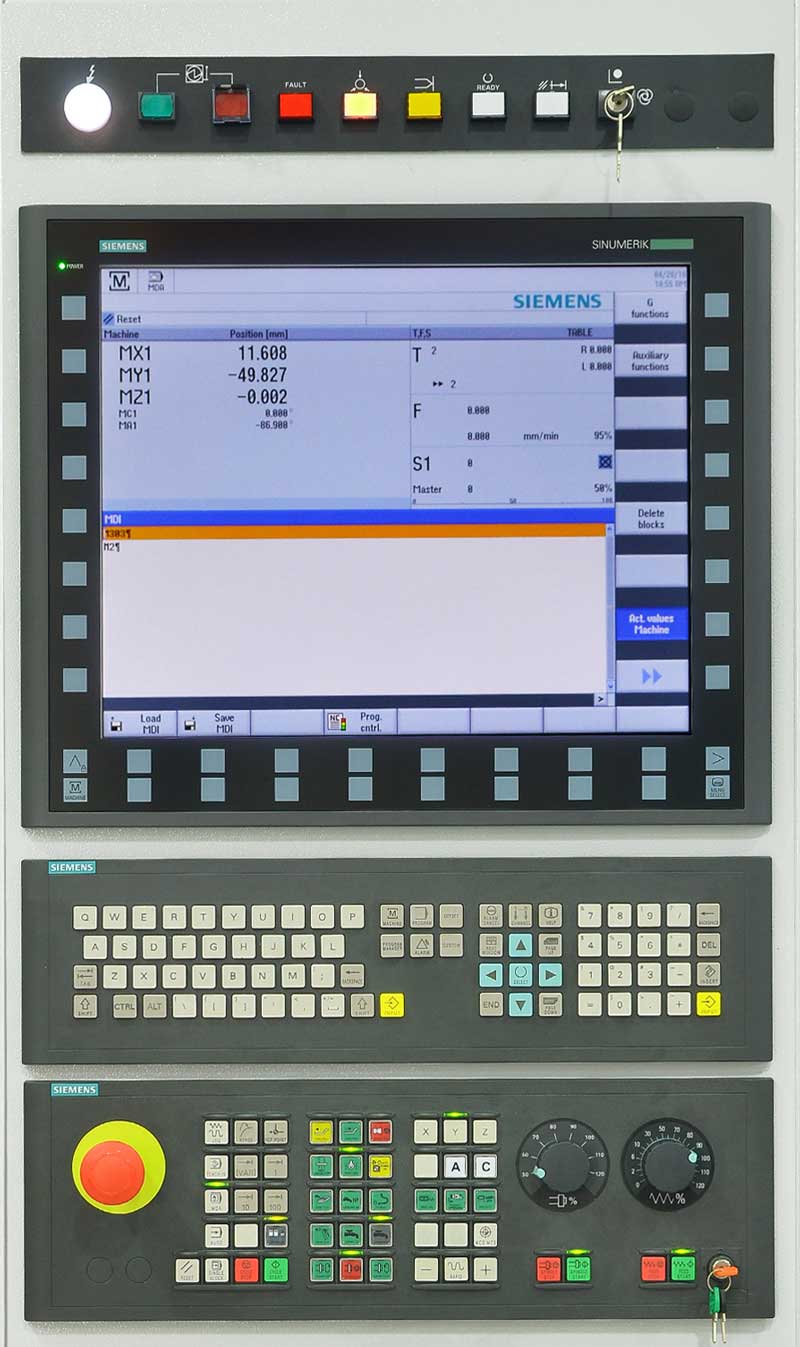

Optional CNC control |

Siemens 840D |

|

Approx. Machine Wheigt |

14.600 kg |

|

Floor Space (L x D x H) |

2.572 mm x 4.623 mm x 3.536 mm |

Features

- 15,000 RPM Direct Coupled Spindle with Oil Chiller & Air/Oil Mist

- Big-Plus® CT 40 Spindle

- 40-station Swing Arm ATC

- CNC Control – Siemens 840 D SL

- Coolant Chip Flush System

- Coolant Wash down Gun-Automatic

- Auto Central Grease Lubrication

- A-Axis Rotary Encoder

- Ball Nut and End Bearing Chiller

- Leveling Pad and Screw

- Retention Knobs

- CTS Preparation with Deublin Rotary Union

- Coolant Through Spindle

- Auto Door Magazine

- Spindle Circular Flushing

- Scraper Type Conveyor

- Auto Power Off

- Work Light

- Three Color Stack Light

Options

- C-Axis Rotary Encoder

- X/Y/Z Axis Linear Scale

- Chip Conveyor, Hinge Type

(W=500)

- Coolant through Spindle (280PSI)

- Mist Collector

(1.5Kw, Airflow 33.3m3/min)

- Renishaw Tool & Part Probe

(OMP40-+OTS)

(TC 52 + TC S4-20)

- Dynamic Collision Monitoring

- 48 Position 40 Taper Tool Magazine

- 60 Position 40 Taper Tool Magazine

- Siemens KinimaticAlignment Software

Siemens or Heidenhain

Siemens 840D SL– 19” TFT LCD display with Innovative capacitive sensor technology

– Programmable Resolution.0001”/.001mm– Inch/Metric data selectionby G-Code

– MDI (Manual Data Input) Operation

– ShopMill

– 3D Simulation

– SINUMERIK Operate

– Animated element operation

– Easy Tool Management

– Measurement cycles

– Transmit and peripheral surface transformation

– CYCLE800

– MDynamics

– Advanced Surface

– Ethernet interface (Data Transfer Capability)

– FTP

– Part Program Storage/Data input/output on:

- 10 MB CNC memory

- 6 GB internal Compact Flash

- USB 2.0

- Network Drive

Heidenhain iTNC 640 FS– 19” TFT display with touchscreen for multi touch operation

– Contouring control– Axes: 20 control loops

– Uniformly digital with HSCIinterface and EnDatinterface

– Storage: HDR hard diskwith 160GB or SSDR solidstate disk with 32GB

– Programming inHEIDENHAINconversational formator according to DIN/ISO

– Comprehensive cyclepackage for milling andturning operations

– Constant surface speedfor turning operations

– Tool-tip radiuscompensation

– Touch probe cycles

– Free contour programming(FK)– Special function for fast3-D machining

– Short block processingtime (0.5 ms)

Conversational programming features offered on the CNC control is the CNC control builder’s standard product, which may not fully support all machine functions. It is recommended the end user reference the control system documentation, or contact the control manufacturer, for further details of use or customization.