|

|

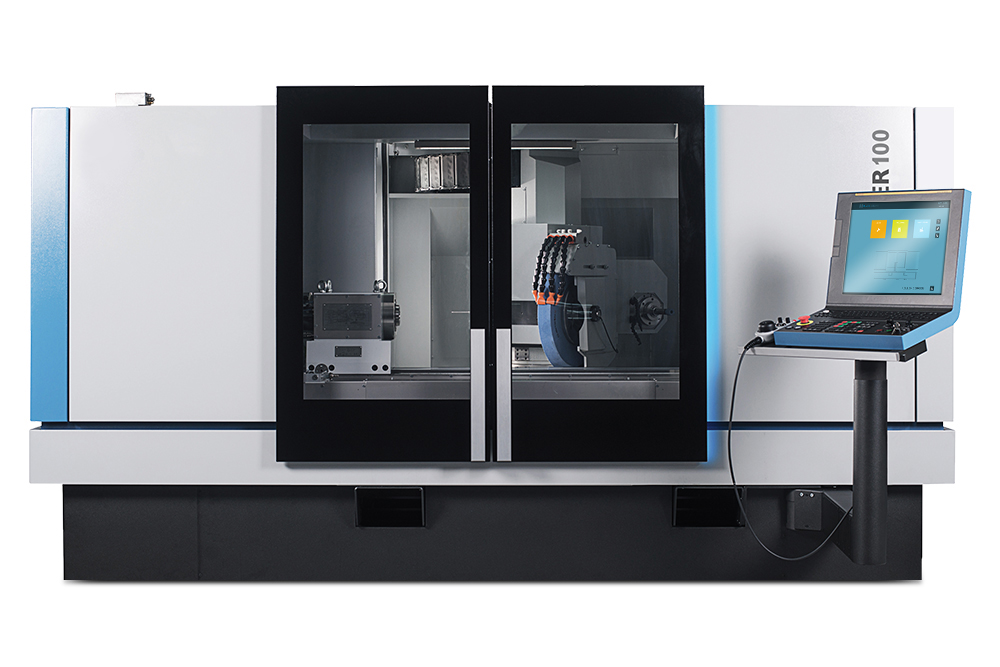

Hauser H45 |

|

Work range |

|

|

Range of adjustment X, Y |

700 x 500 mm |

|

Vertical adjustment of grinding head (W) |

500 mm |

|

Clearance between table surface and U-axis carrier plate for grinding motor |

785 mm |

|

Distance between upright columns |

750 mm |

|

|

|

|

Diameter ground in planetary mode, with grinding wheel Ø 50 mm/70S: |

|

|

grinding motor 70S in U-axis center position, automatic grinding mode |

144 mm (max.) |

|

grinding motor 70S with extension plates, semi-automatic mode |

360 mm (max.) |

|

Diameter ground in planetary mode, with grinding wheel Ø 100 mm/40S: |

|

|

grinding motor 40S in U-axis center position, automatic grinding mode |

194 mm (max.) |

|

grinding motor 40S with extension plates, semi-automatic mode |

360 mm (max.) |

|

Taper grinding, included angle (divergent and convergent) |

120 degree max. |

|

Table |

|

|

Working surface |

770 x 630 mm |

|

6/7 T-slots, width |

14 mm |

|

Permissible table load |

500 kg max. |

|

Feeds |

|

|

Table and saddle X, Y, W |

|

|

Machining speed |

0-2'000 mm/min |

|

Traversing speed |

4'000 mm/min |

|

Grinding spindle Z, C, U |

|

|

Diameter of the spindle sleeve |

125 mm |

|

Basic machine is prepared for use of the following grinding spindle speeds: |

|

|

for electric grinding motor 40S, infinitely adjustable & programmable |

4'000-40'000 min-1 |

|

for electric grinding motor 22S, infinitely adjustable & programmable |

4'500-22'500 min-1 |

|

for electric grinding motor 45S, infinitely adjustable & programmable |

9'000-45'000 min-1 |

|

for electric grinding motor 70S, infinitely adjustable & programmable |

9'000-70'000 min-1 |

|

System to allow use of grinding turbine T13 |

up to 130'000 min-1 |

|

C-axis planetary mode: |

|

|

Planetary mode, infinitely adjustable and programmable |

5-350 min-1 |

|

C-axis follow-up mode, AC servo drive |

up to 10 min-1 |

|

Z-axis in alternating stroke mode: |

|

|

Z-alternating stroke movement, infinitely adjustable |

Vmin. 0,500 mm/min |

|

Z-alternating stroke movement, infinitely adjustable |

Vmax. 22’000 mm/min |

|

Z-stroke frequency |

8 Hz max. |

|

Z-stroke length, infinitely adjustable |

0.1 up to 170 mm |

|

U-axis radial travel capacity (in CNC-mode) |

von –3 up to +47 mm |

The Hauser™ H45/H55 Series is an expandable jig grinding machine, from simple bore and form grinding machine to fully automatic high-tech grinding and hard milling cell. Now with a new Hauser jig grinding/hard milling head which provides an unparalleled variety of grinding and milling strategies with its Z, C and U configuration. With its high grade rigidity and stiffness plus a significantly boosted stroke speed & frequency this has lead to the doubling of stock removal capacity, reducing grinding cycle time, whilst cutting in half spark out time. Hydrostatic guided spindle bearing system allows circular accuracies better than 0,5 µm in planetary grinding and an unparalleled U axis capacity up to +47 mm increases the grinding autonomy. Automated taper grinding is available with Z U axis interpolation. Thanks to this most modern grinding head technology, the combination of high accurate jig grinding with complementary hard milling has become a Hauser focal point. Usable surface on the H45 is 770 x 630 mm, permissible load 500 kg and on the H55 the usable surface is 1440 x 860 mm, permissable load 800kg/optional 1500 kg.

Featuring a robust, distortion-resistant module and consequent lay-out with regard to thermal stability

GUIDEWAYS / MEASURING SYSTEMS / AXES DRIVES

- Sliding guideways wherever required

- Linear guideways wherever possible

- Absolutely smooth stroke reversal •Measuring systems optimally positioned with regard to the measuring technique • Axes drives in the centre of friction

GUIDEWAYS

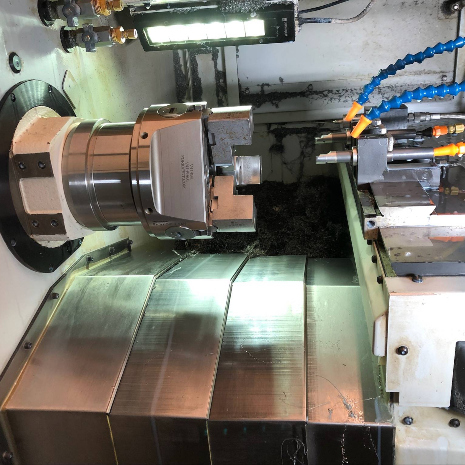

- Scraped sliding guideways in X and Y axis •Oil pressurized guideway- lubricating system, to avoid stick-slip effect ATC automatic tool changer ATC automatic tool changer with 12 magazine positions, permitting automatic machining with grinding wheels from Ø 3 mm to Ø 50 mm (alternatively with grinding wheels from Ø 0,3 mm to Ø 5 mm)

ATC AUTOMATIC TOOL CHANGER

- ATC automatic tool changer with 12 magazine positions, permitting automatic machining with grinding wheels from Ø 3 mm to Ø 50 mm (alternatively with grinding wheels from Ø 0,3 mm to Ø 5 mm).

GRINDING MOTOR

- Grinding motor 70S ATC with its extremely wide range of application, from 9000 min-1 to 70000 min-1. This grinding motor, and its state-of-the-art design, is an absolute must for getting optimal use

out of the grinding tool changer.

CONTROL SYSTEM

As standard, the X,Y, C, U, Z and W axes are CNC controlled. Based

on the FANUC 30i control with integrated PC, we have created HAUSER SOFTWARE CYCLES, ensuring that the control will perfectly cover all the special requirements of jig grinding.