|

|

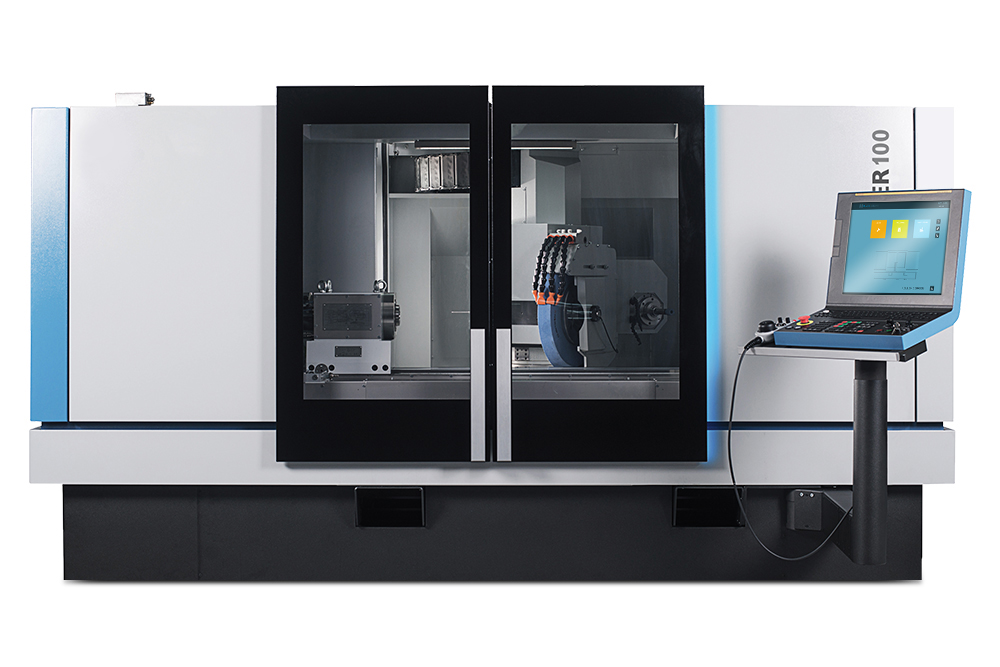

Tschudin T35 |

|

Dimensions |

|

|

Distance between centers |

400 mm |

|

Grinding length |

400 mm |

|

Center height |

125/175 mm |

|

Max. workpiece diameter |

249 mm |

|

Workpiece weight |

|

|

Between centers |

150 kg |

|

Base/Table slide |

|

|

Travel Z-Axis |

600 mm |

|

Rapid Traverse |

15 m/min |

|

Resolution |

0.1 µm |

|

Wheelhead OD |

|

|

Wheel (appl. spez.) |

400 - 500 mm x 80 mm x 203.2 mm |

|

Diameter |

up to 600 mm |

|

Width |

up to 120 mm |

|

opt |

500 mm x 120 mm x 203.2 mm |

|

Peripheral roller bearing |

0-120 m/s |

|

Peripheral hydrodynamic |

45/60 m/s |

|

Spindle speed |

V const (opt) min-1 |

|

Motor output |

10 kW (opt. up to 20) |

|

Workhead |

|

|

Spindle speed |

5 - 1,500 min-1 (opt. 3,000) |

|

Motor output |

2.1 kW |

|

Spindle nose taper |

MT5 / Ø 70 mm // MT6 / Ø 90 mm |

|

Spindle nose bore |

34 mm |

|

Spindle torque |

20 Nm |

|

Tailstock |

|

|

Sleeve retraction |

80 mm |

|

Internal taper |

MT3 |

|

Control |

Bosch / Siemens |

The Tschudin T35 is the definitive modular production cylindrical grinding machine for satisfying the most varied applications needs in the production of medium and large series. Hydrostatic guides and a large application range, from small integrated handling to complex systems with autonomous cells. The production machine offers synchronous processing, prism and rod grinding, and integration of additional operations.

Axes configuration

- Straight or angular

- Range +6° to -30° configurable

Burr-free grinding

- Several patented processes

- Production of sharper, burr-free edges

Prismatic grinding system

- Very efficient production grinding process

- Shortest part changing time, rapid retooling

- Fully integrated handling with modular peripherals and great autonomy

Match grinding

- Highly accurate automatic process with several extension possibilities

- Automatic cylindrical correction within 0.1μm range

Grinding from hardened bar stock

- High precision parts can be finish-ground directly from hardened bar stock

- Optimal process to produce non-machined parts with high precision centers and minimum overmeasure for subsequent operations

Automation

- Modular concept for peripherals and handling systems

- Wide application range from small integrated handling to complex systems with autonomous cells

- Unrestricted use, water or oil

- Customer-specific solutions possible

Control systems

- Siemens 840 D

- Bosch Rexroth MTX

The software for the control system was developed by grinding specialists and thus permits optimum programming of grinding and dressing processes. A particular highlight is the integration of part-specific features such as measurement technology, handling and additional processing units.