|

|

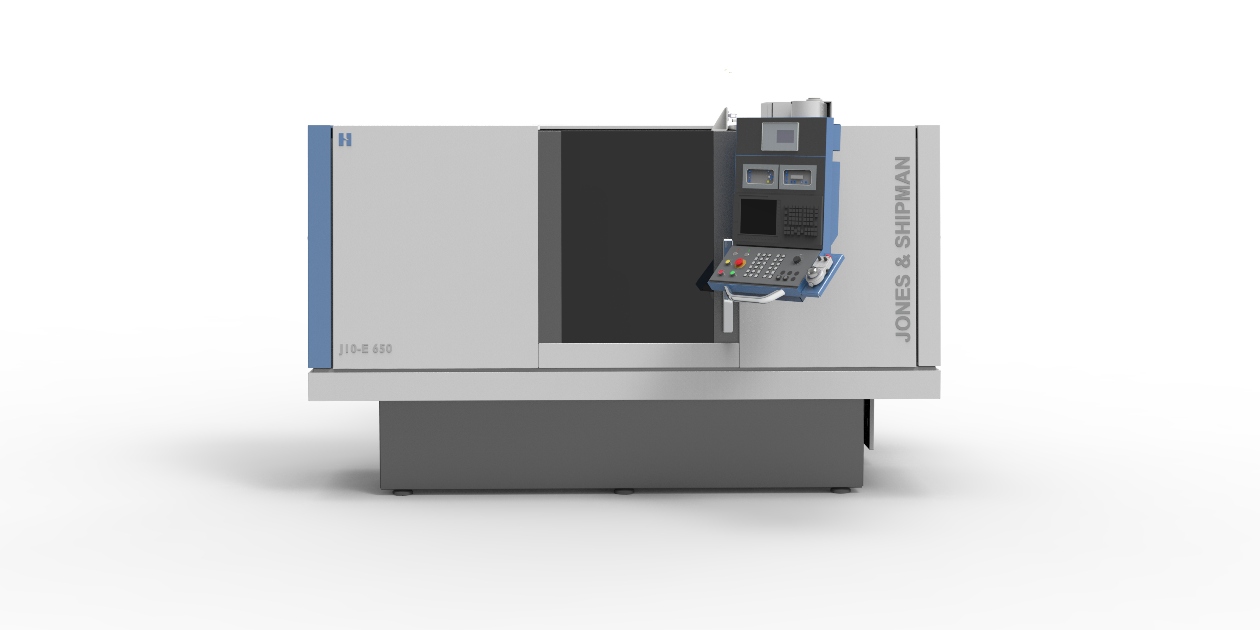

HAUSER 2000 |

|

Work range |

|

|

Range of adjustment X, Y |

550 x 300 mm |

|

Vertical adjustment of grinding head (W) |

450 mm |

|

Clearance between table top and U-axis reception face grinding motors |

745 mm max. |

|

Clearance between table top and grinding motor reception nose (70HS) |

0-550 mm |

|

|

|

|

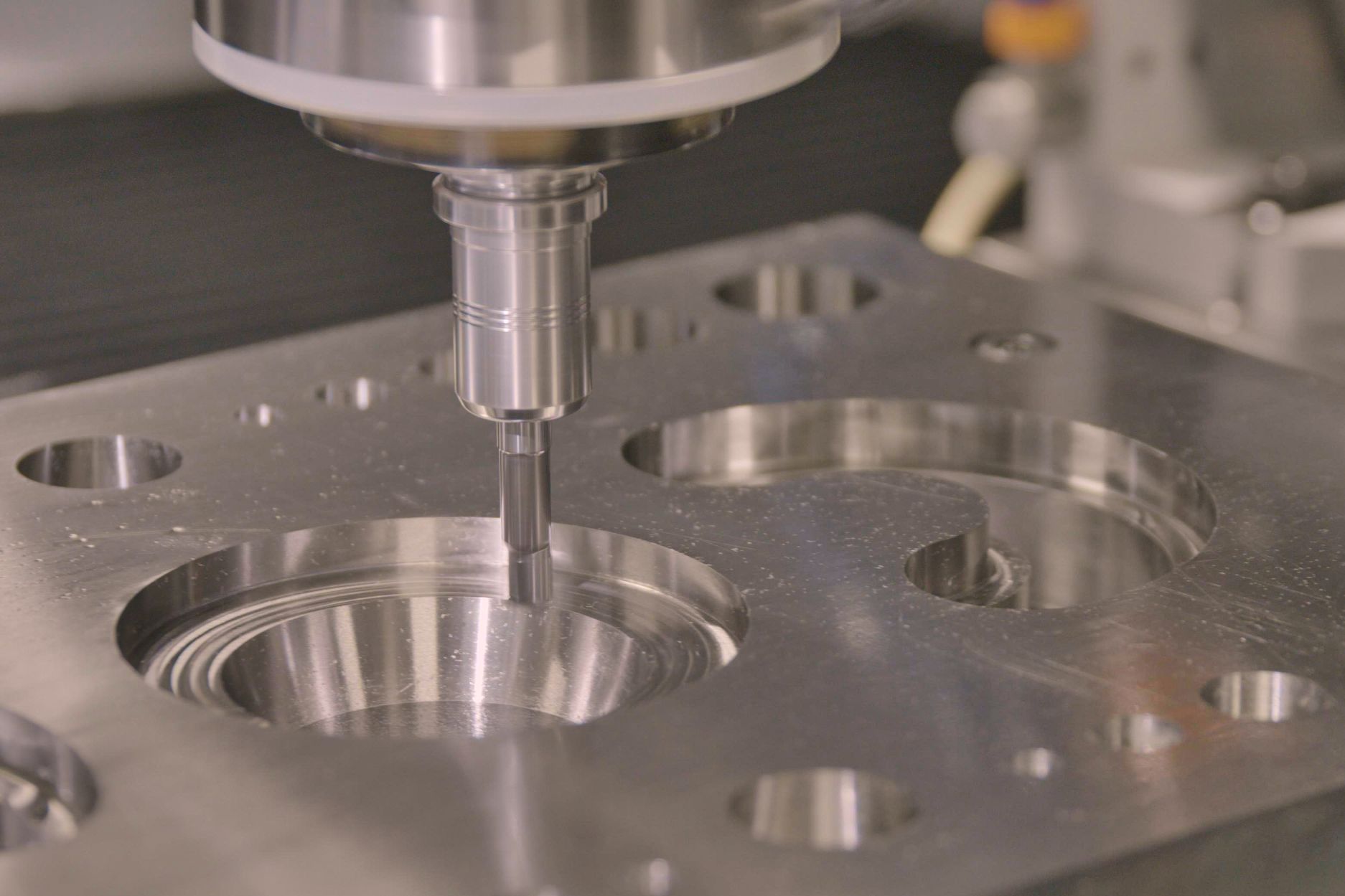

Diameter ground in planetary mode, with grinding wheel Ø 50 mm/70S: |

|

|

grinding motor 70S in U-axis center position, automatic grinding mode |

144 mm (max.) |

|

grinding motor 70S with extension plates, semi-automatic mode |

360 mm (max.) |

|

Diameter ground in planetary mode, with grinding wheel Ø 100 mm/40S: |

|

|

grinding motor 40S in U-axis center position, automatic grinding mode |

194 mm (max.) |

|

grinding motor 40S with extension plates, semi-automatic mode |

360 mm (max.) |

|

Taper grinding, included angle, divergent and convergent (Option) |

120 degree max. |

|

Table |

|

|

Working surface |

650 x 432 mm |

|

6 T-slots, width |

10 mm |

|

Permissible table load |

300 kg max. |

|

Feeds |

|

|

Table and saddle X, Y: |

|

|

Machining speed |

0-4'000 mm/min |

|

Traversing speed |

8'000 mm/min |

|

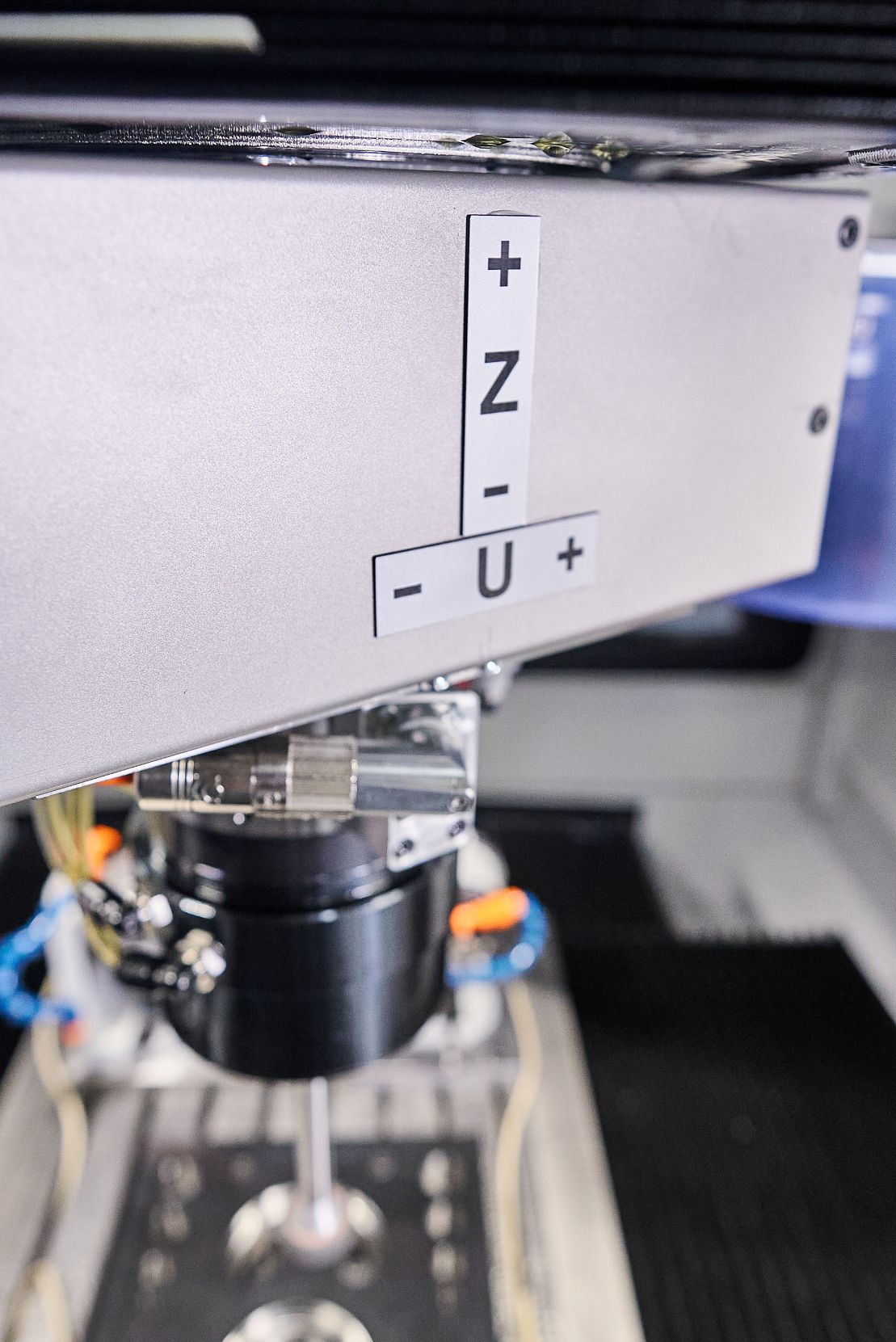

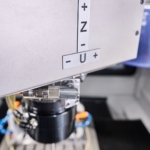

Grinding spindle Z, C, U |

|

|

Diameter of the spindle sleeve |

125 mm |

|

Basic machine is prepared for use of the following grinding spindle speeds: |

|

|

for electric grinding motor 40S, infinitely adjustable & programmable |

4'000-40'000 min-1 |

|

for electric grinding motor 70S, infinitely adjustable & programmable |

9'000-70'000 min-1 |

|

System to activate grinding turbine T13 |

up to 150'000 min-1 |

|

C-axis planetary mode: |

|

|

Planetary mode, infinitely adjustable and programmable |

1-350 min-1 |

|

C-axis follow-up mode, AC servo drive |

up to 10 min-1 |

|

Z-axis in alternating stroke mode: |

|

|

Z-alternating stroke movement, infinitely adjustable |

Vmin. 0,500 mm/min |

|

Z-alternating stroke movement, infinitely adjustable |

Vmax. 26’000 mm/min |

|

Z-stroke frequency |

10 Hz max. |

|

Z-stroke length, infinitely adjustable |

0.1 up to 170 mm |

|

U-axis radial travel capacity (in CNC-mode) |

von –3 up to +47 mm |

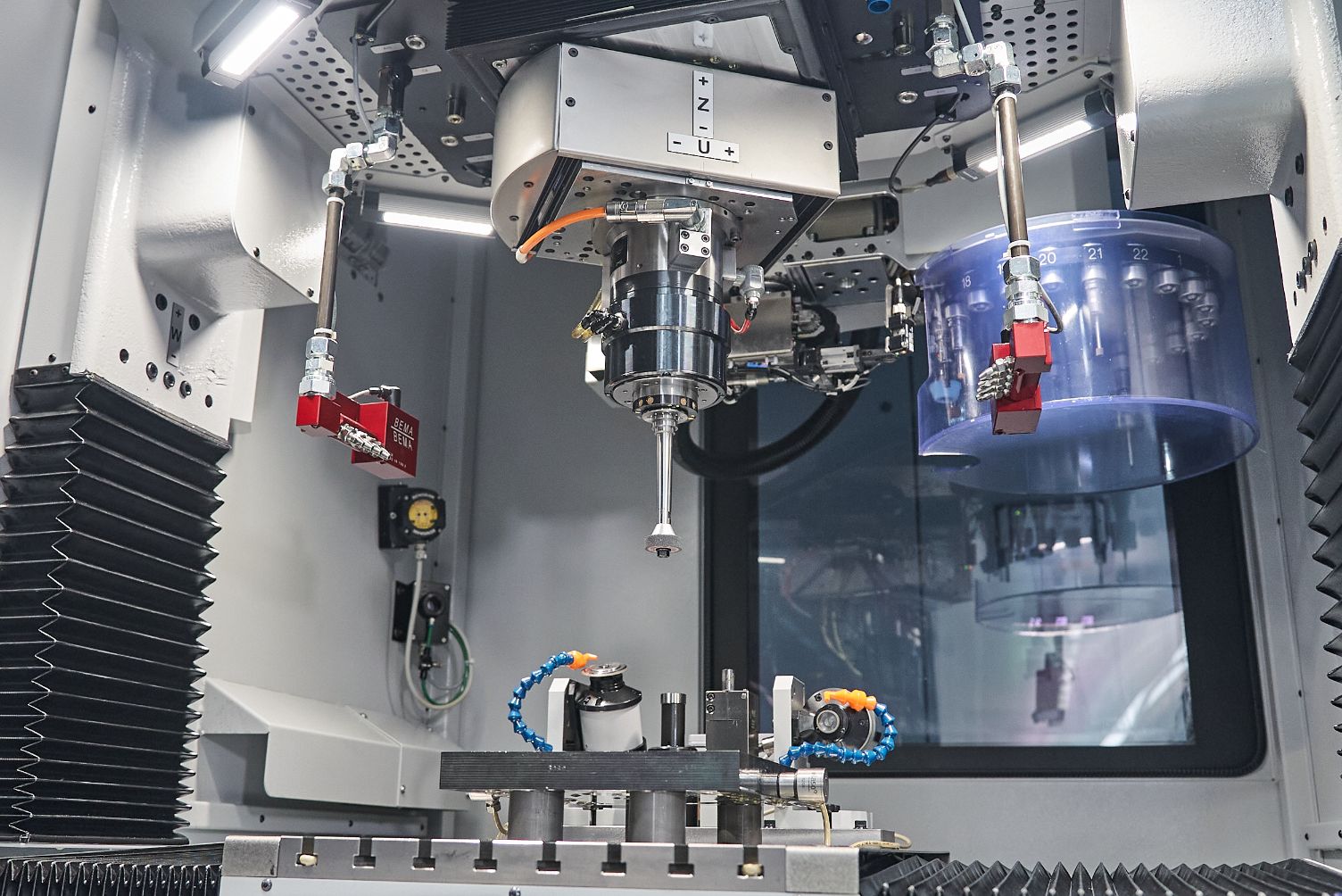

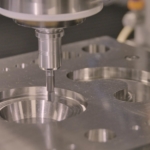

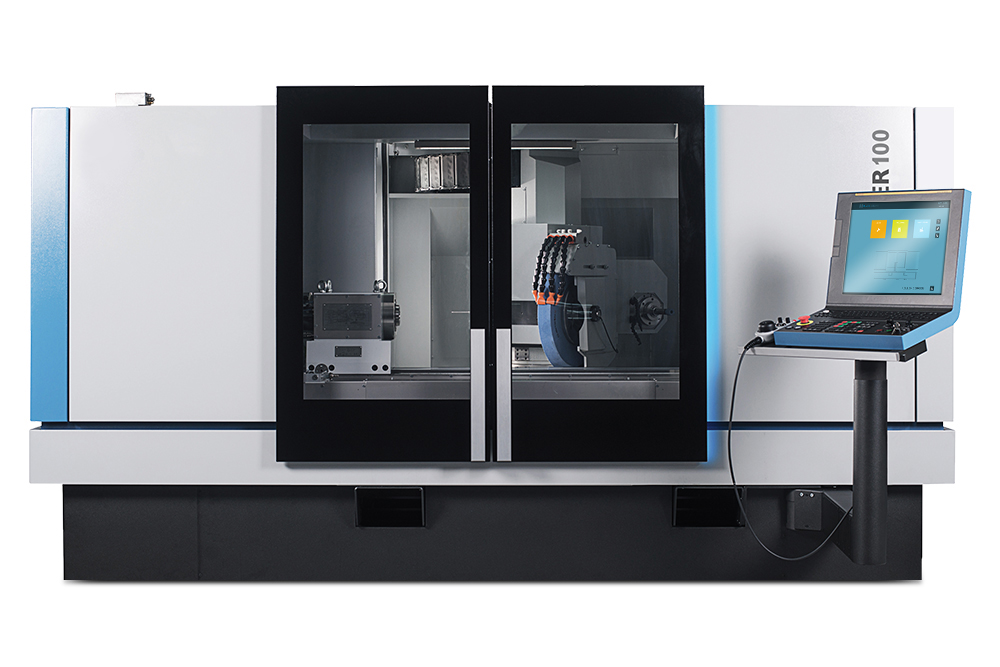

The new Hauser™ 2000, the successor to the H35-400 model, is a universal jig grinder with proven technical features such as automatic taper grinding, automatic grinding tool changer (ATC) and automatic pallet changer (APC). It can be expanded easily to an autonomous grinding unit. The Hauser 2000 not only meets the demand of the market for combined grinding and hard milling on a single jig grinder, but also enables further improvements in machining precision to meet future requirements. The main technical feature is the dual-frame design, which significantly increases the rigidity of the grinder and therefore ensures even higher precision. In this box-type design, the machining head is positioned centrally within the machine frame, thus enabling machining forces to be optimally controlled. Almost no transverse forces are created – the prerequisite for ultra-high geometric precision machining. Since the tool machining point is located at the center of the machine, practically all thermal expansion effects are eliminated.

With higher dynamic axis movements and significantly greater rigidity, the Hauser 2000 gives the best possible conditions for finishing with hard precision milling. The overall result is a significant increase in productivity not only for the ultra-precise grinding processes on the machine but also for hard milling.

- Measuring probe for the automatic best fit of work-pieces and for the establishment of measuring protocols.

- A- and A-B rotary and rotary tilting axes in customized version are available as additional units.

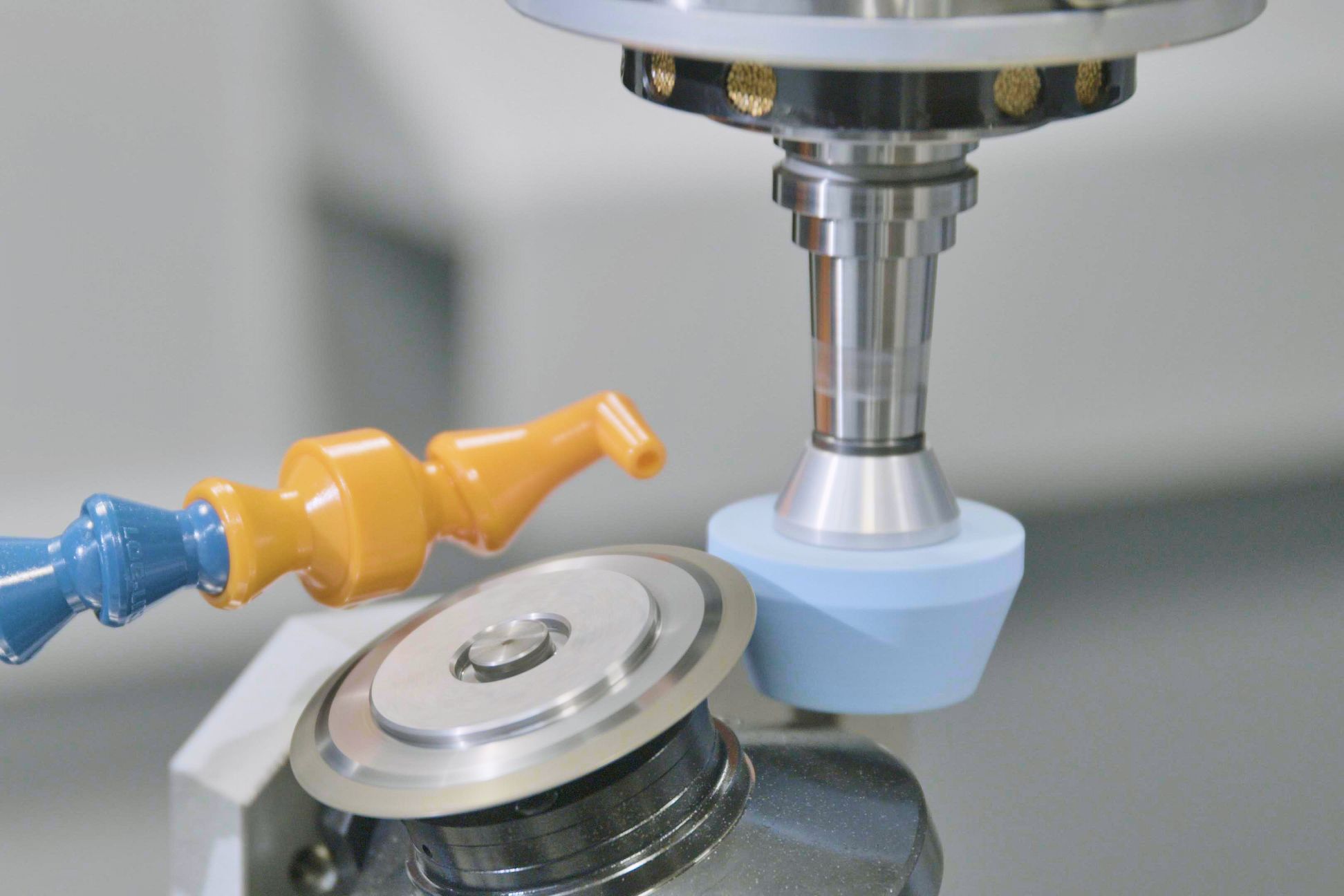

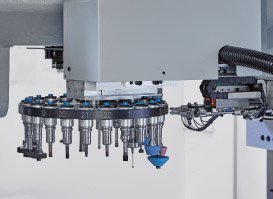

- Grinding motor 70S ATC with its extremely wide range of application, from 9000 min-1 to 70000 min-1. This grinding motor, and its state of the arts design is an absolute must for getting optimal use out of the grinding tool changer.

- CBN dressing unit with HF drive, for conditioning (dressing) vitrified and resinoid bond CBN grinding wheels.

- MSS – multi-sensor-system for automatic suppression of “air grinding” and for automatic grinding wheel calibration.

- Automated taper grinding with help of Z-U-axis interpolation.

FANUC Series 30i

- Max. number of path: 10 – 15 path

- Max. total number of control axes:

- 96 axes (72 feed axes, 24 spindles) / 10 path

- 72 axes (56 feed axes, 16 spindles) / 15 path

- Max. number of simultaneous control axes: 24 axes

The capability of this model helps to realize an advanced multi axis machine tool. Thanks to a number of control axes, various machining processes can be executed at the same time. Its 5-axis machining function can achieve the machining of complex shape. It has the flexibility to control various types of machine tools.