|

Specification |

|

Specification |

|

|

Capacity |

|

Wheel Slide |

|

|

Center Height |

190 mm |

Total infeed |

350 mm |

|

Swiveling diameter |

Ø380 mm |

Max. travel speed |

10 m/min |

|

Distance between centers |

650/1000 mm |

Min. programmable increment |

0.0001 mm |

|

Weight between centers |

100 kg |

Resolution (Option) |

0.00005 mm |

|

Wheel head |

|

Table slide |

|

|

Wheel speed |

Max. 63 m/s |

Max. stroke length |

750/1150 mm |

|

Wheel size |

Ø500x80(150)x203.2 mm |

Max. travel speed |

12 m/min |

|

Main motor power |

9/15 kW |

Min. programmable increment |

0.0001 mm |

|

Work head |

|

Resolution (Option) |

0.00005 mm |

|

Speed range |

0-1000 rpm |

Control system |

|

|

Spindle nose taper |

A2-6 |

CNC control |

Fanuc CNC 0i |

|

Motor power |

1.8kW |

Software |

GUI |

|

Output torque |

11 Nm |

Display |

10.4" TFT |

|

Weight load with chuck |

48 kg |

Interface |

USB/Ethernet/Rs232 |

|

Tailstock |

|

Environment |

|

|

Poppet diameter |

Ø60 mm |

Noise |

<75 dB(A) |

|

Center travel |

30 mm |

Ambient temperature |

0~40°C |

|

Poppet taper |

MT 4 |

Humidity |

≤75% |

|

Fine adjustment range |

+/- 100 μm |

Miscellaneous |

|

|

Graduation |

Ø0.0005 mm |

Color of enclosure |

RAL 7035 light gray |

|

|

|

Color of bed |

RAL 7021 dark gray |

|

|

|

Gross weight |

6200/7200 kg |

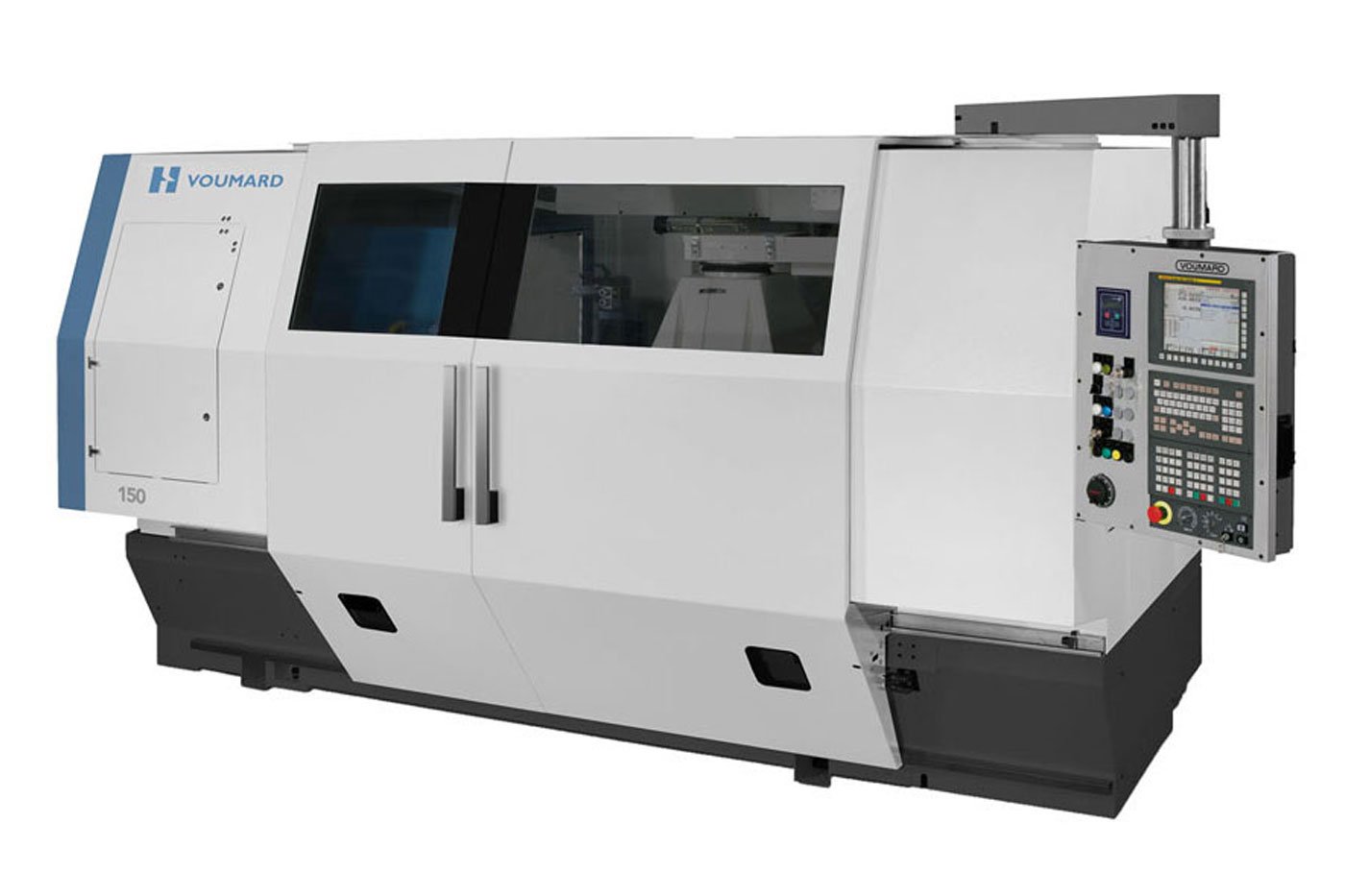

Precise and efficient grinding in one compact package.

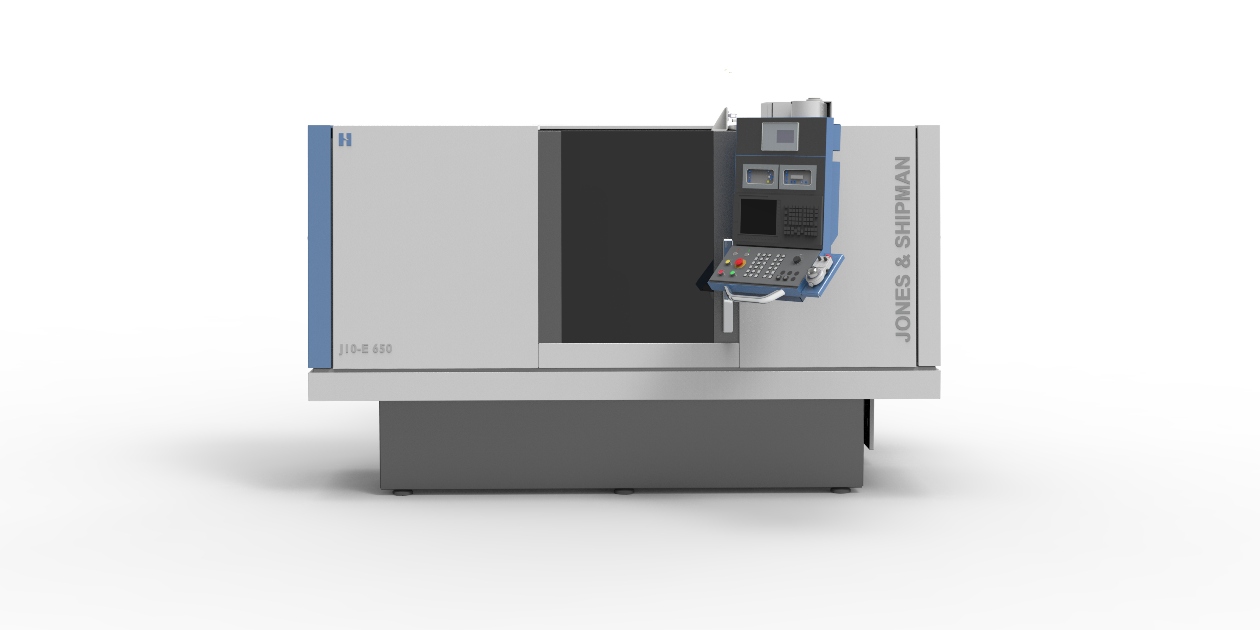

The Jones & Shipman 10 cylindrical grinding machine is an ideal solution for the production cylindrical grinding of small to midsized components. The Jones & Shipman 10 grinder can be equipped with either a straight or angular plunge wheelhead with a maximum wheel size of 5.9”. The J10 cylindrical grinder is the perfect combination of performance-to-price and was engineered with customers’ requirements in mind. The machine has been designed with the backing of technical fluency of the entire Hardinge Grinding portfolio with strict manufacturing processes in accordance to global standards, guaranteeing the highest quality for each machine. Our user-friendly graphical software is perfect for a production environment and is easy to get users running parts in no time.

Best-in-class features and options

-

EFFICIENCY

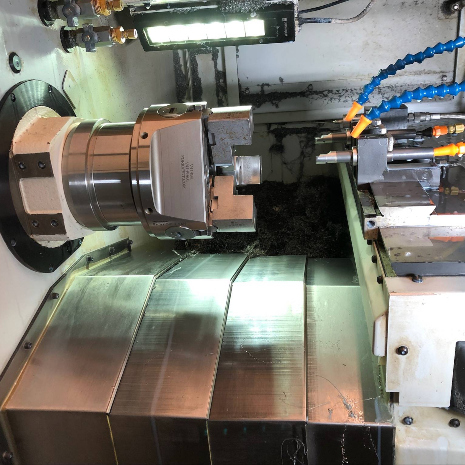

Robust construction & innovative design of machinebed, wheelhead, and workhead ensure a higher efficient grinding process.

-

RELIABILITY

Well-known world top brand key components guarantee the machine working with stability and accuracy retention in its lifetime.

-

PRECISION

Hardinge globally unified standard of design, manufacturing and assembly allows each machine to every customer is built with world-class quality.

-

EASE-OF-USE

Easy to follow set-up pages allow the operator to digitize diamond and wheel positions by means of a simple user-friendly interface.

-

SAFETY

Full enclosure, bullet-proof glass windows, wheel protection, one button fall back, emergency button and interlock etc. offer operator a safe working environment.

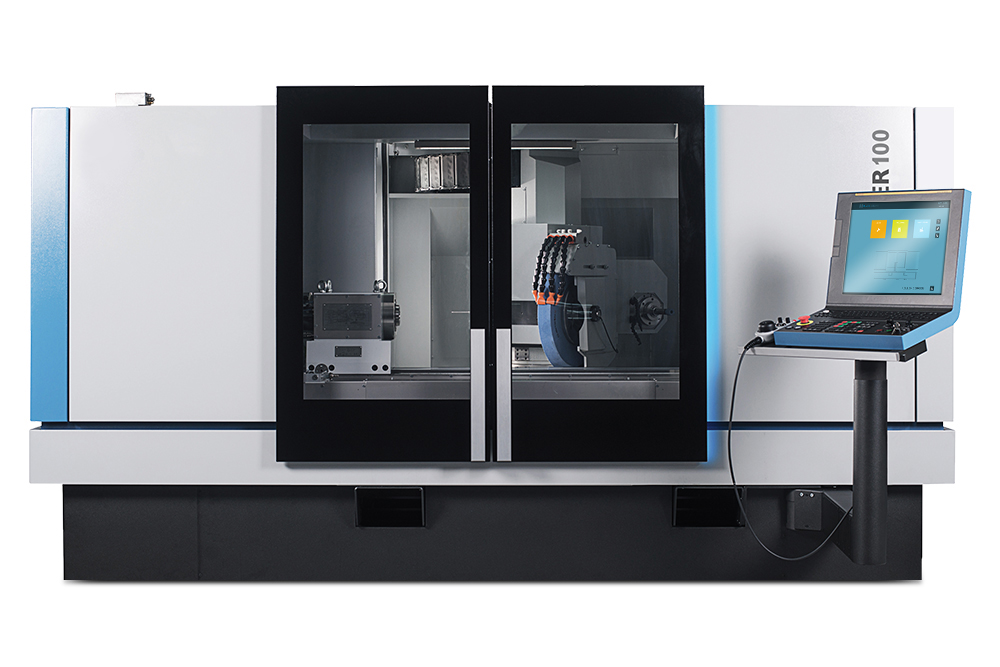

Controls Features

- Easy Graphic User Interface

- Quick and simple input

- Large capacity solid-state memory

- No hard drive

- Multi wheel datum management

- Remote diagnosis and assistance

- Ethernet and RS232 interface

- USB and flashcard

- Background edit function

- Safe code set

Software Info

Featuring the latest Fanuc CNC 0i control system, the software is designed to minimize set-up times, which is fundamental in reducing machined component costs whilst maximizing manufacturing output.

Easy to follow set-up pages allow the operator to digitize diamond and wheel positions by means of a simple user-friendly touchscreen interface. Graphical images, which represent programs and set-ups, are simply touched to program, providing quick and simple input. This graphical programming removes the requirement for operators to input complex code, subsequently reducing set-up and operator training costs. ISO programming is fully supported, and codes can also be easily viewed and used at any time as each method of modification updates the other seamlessly within the program.

Jones & Shipman 10 Grinding Applications

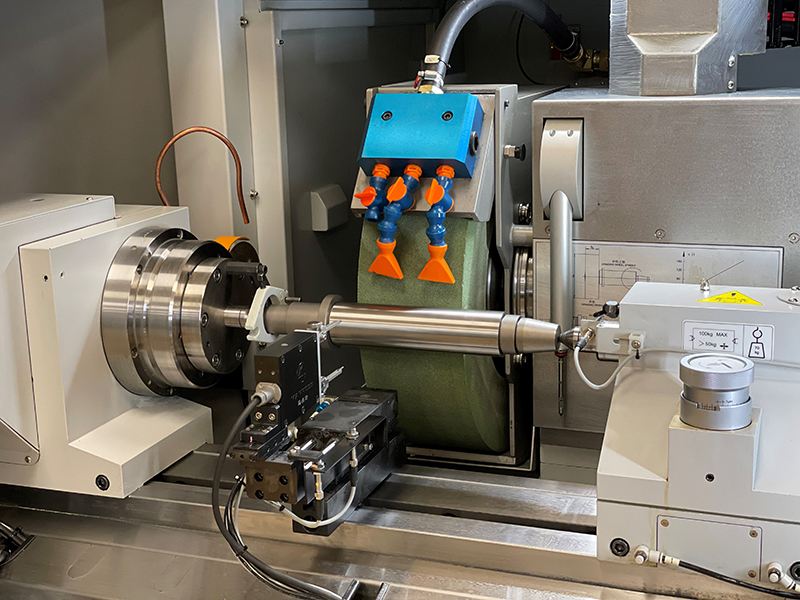

- RV Reducers

- Transmission Shaft Grinding

- Crankshaft Pins

Jones & Shipman 10

User Manual

Contains information about proper maintenance and care of your J10 grinding machine