|

|

ELITE 42 ULTRA |

ELITE 51 ULTRA |

ELITE 65 ULTRA |

|

Spindle Speed |

6000 RPM |

5000 RPM |

4200 RPM |

|

Collet Size |

16C |

20C |

25C |

|

Chuck Size |

6" |

8" |

8" |

|

Turning Diameter |

284 mm |

284 mm |

411 mm |

|

Turning Length |

456 mm |

456 mm |

630 mm |

- It employs the most reliable servo motor and drive system in the industry.

- The efficient servo motor phase drive system provides excellent machining capabilities for the machine tool.

- The T-type turret with 12 tool positions is provided as a standard configuration.

- The non-contact magnetic encoder eliminates the need to use belts and enhances the overall reliability

- The one-degree indexing function of spindle is available as a standard configuration.

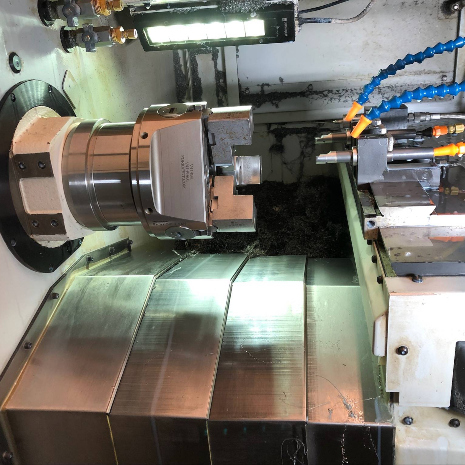

- The original Hardinge high-precision spindle imported from America is compacted with the unique hardinge “Collet-Ready” structure, so it can utilize 3-jaw chuck or precision spring collets without any adapter.

- The double-winding spindle motor provides efficient heavy-duty cutting capabilities.

- Both the machine tool body and all castings are made of high-quality gray cast iron, presenting wonderful rigidity, durability and thermal stability.

- The environmentally friendly centralized grease lubrication minimizes the overall maintenance costs of machine tool.

- The heavy-duty linear guide rail system provides optimum stiffness and rigidity, resulting in direct advantages such as greater cutting capability and longer machine tool service life.

- The heavy-duty double-nut lead screw with fixing, pretensioning and extending functions is of Grade C2 and ensure outstanding rigidity, machine tool accuracy and repeatability.

- The 30 degree overall tilt machine tool body is designed with reinforcing ribs for additional reinforcement.

- Featuring a large rectangle hard rail, the fully programmable controlled Morse No. 5 hydraulic tailstock achieves optimum rigidity.

- All machine tools are strictly detected by lasers as per ISO 230-2 1997 quality standards.

The standard configuration includes:

- X-axis/Z-axis grating ruler

- Spindle oil cooler

- Spindle reference point (servo lock)

- Rigid tapper

- Runtime and workpiece counter

- Spindle releasing/clamping pedal switch

- Chip conveyor interface

- Swing-type CNC panel

- Air gun (including quick release connector)

- Tri-color lamp

- Complete set of operation manual, programming manual and service manual

Fanuc OiTF or Siemens 828D