|

|

TALENT 42 |

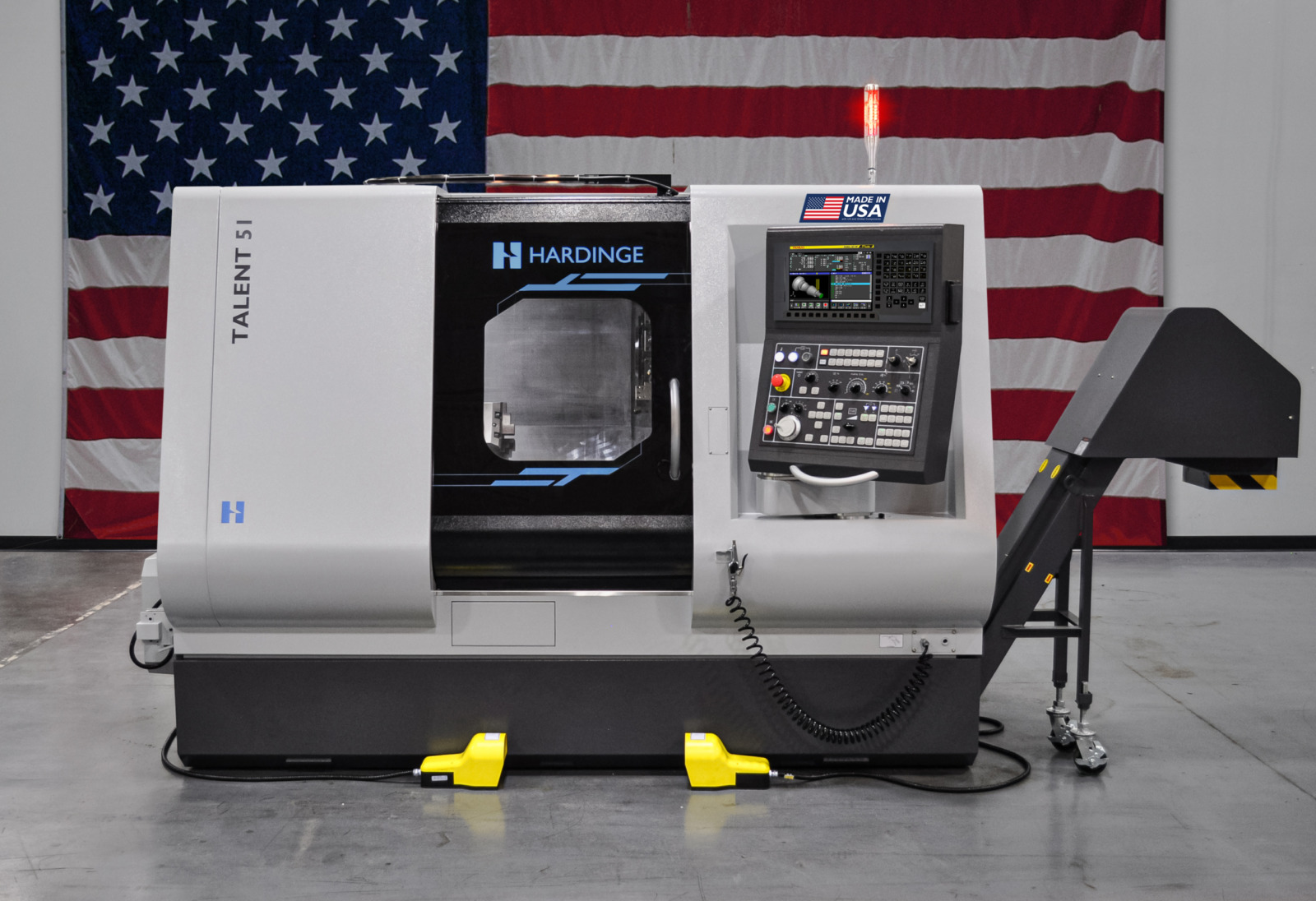

TALENT 51 |

|

Spindle HP |

14.75 HP (11 kW) |

14.75 HP (11 kW) |

|

Spindle Speed |

6,000 RPM |

5,000 RPM |

|

Chuck Size |

6" (150 mm) |

8" (200 mm) |

|

Max. Machining Length |

25.6” (651 mm) |

24.88” (632 mm) |

|

Max. Machining Diameter |

11.41" (290 mm) |

11.41" (290 mm) |

|

Bar Size |

1.65” (42 mm) |

2” (51 mm) |

|

No. Turret Stations |

12 Station (BMT-45) |

12 Station (BMT-45) |

|

CNC Control Unit |

FANUC 0i-TF |

FANUC 0i-TF |

|

Approx. Machine Weight |

12,786 lbs (5,800 kg) |

12,786 lbs (5,800 kg) |

|

Floor Space |

114.69” x 71.42” x 76.06”

(2,913 mm x 1,814 mm x 1,932 mm) |

114.69” x 71.42” x 76.06”

(2,913 mm x 1,814 mm x 1,932 mm) |

The General-Precision Multifunction CNC Lathe

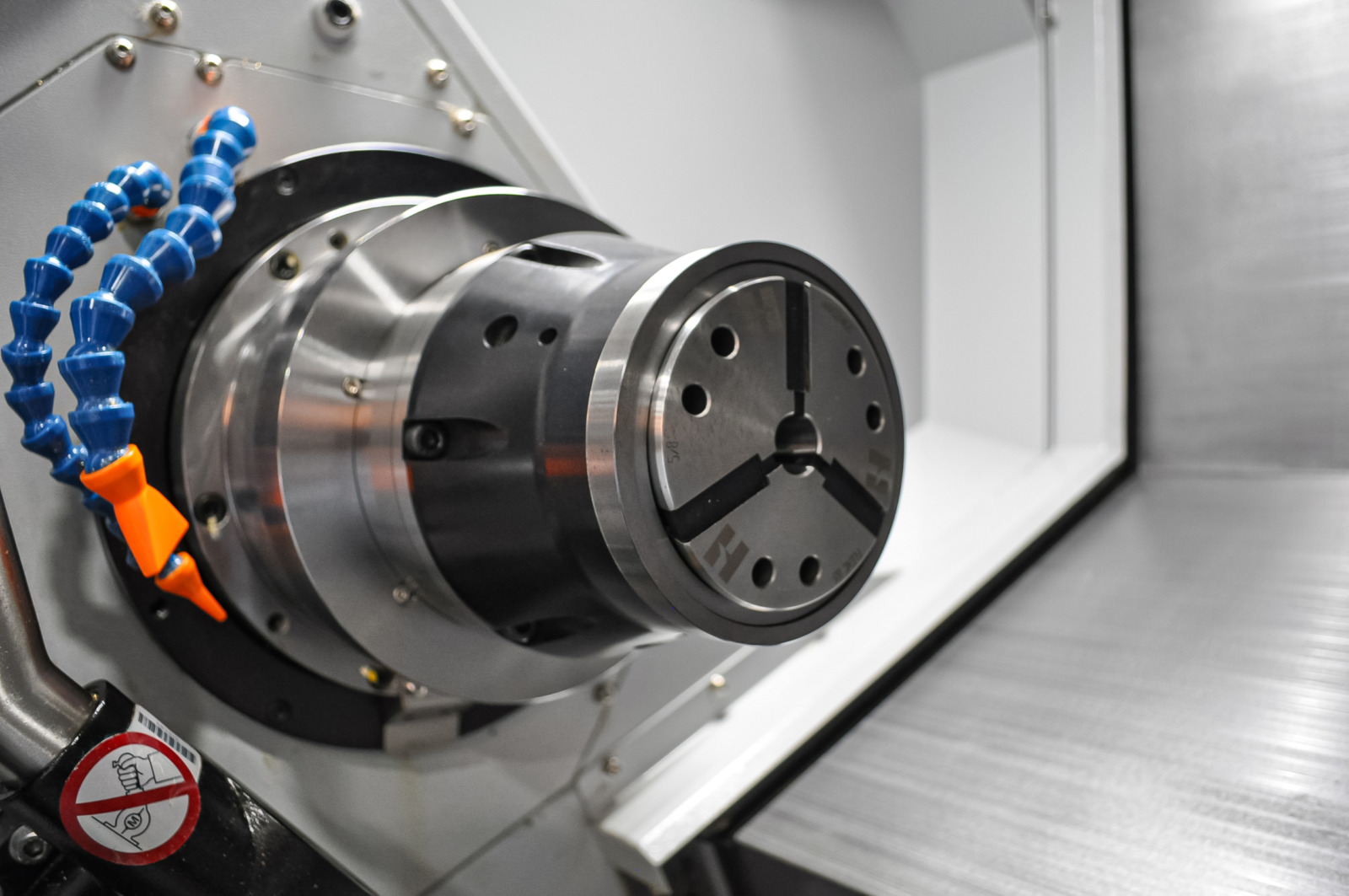

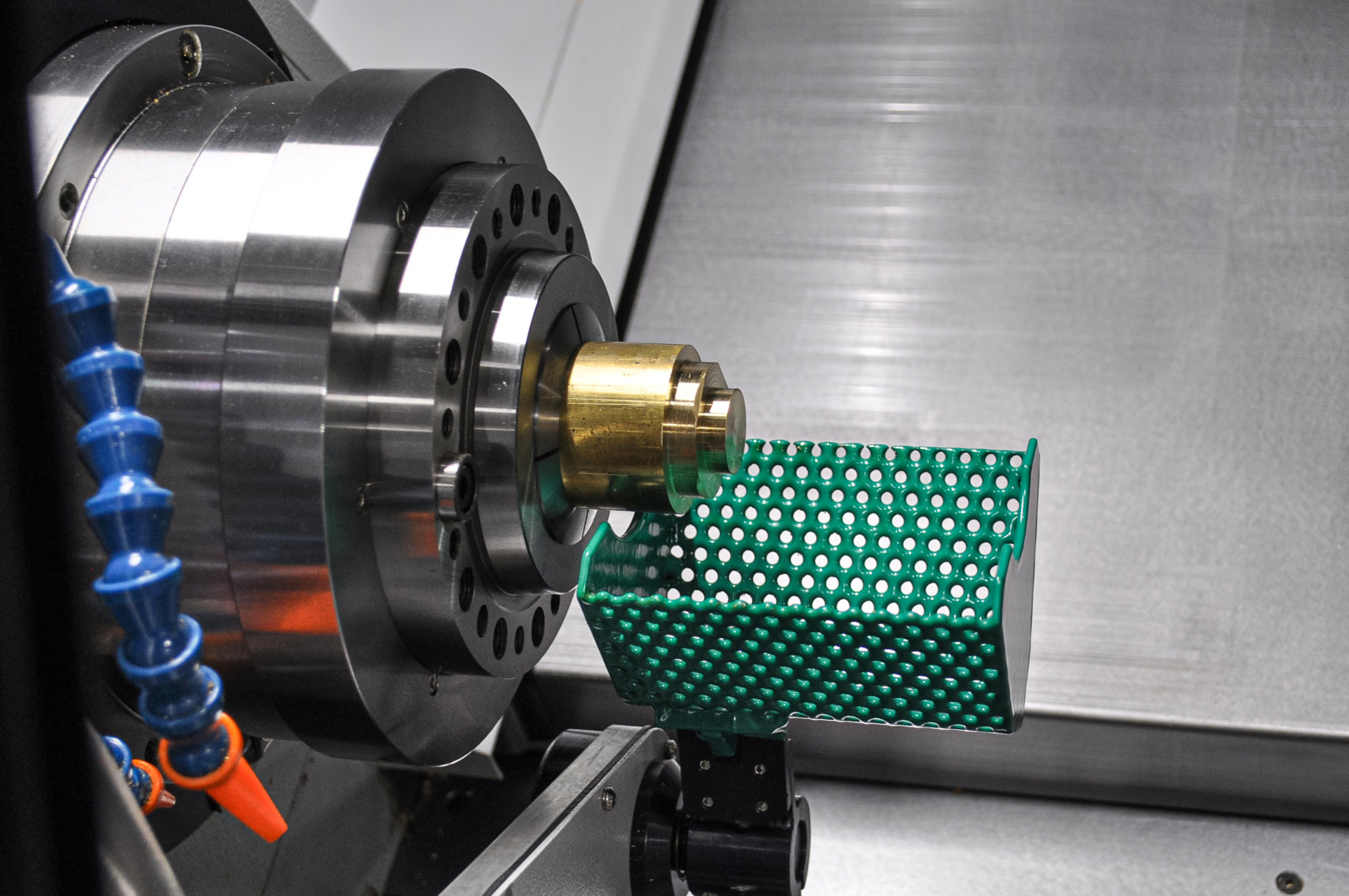

The Hardinge TALENT Series machines offer an exceptional combination of features for accuracy, flexibility and durability in a compact design. The unique collet-ready main and sub- spindle design will increase part accuracy and improve surface finish. The TALENT® Series offers two separate base structures, short bed and standard bed lengths, which feature a robust one-piece cast iron base, heavy duty roller linear guideways and ballscrews, with many standard value-added features – thru- tool and headwall coolant, foot switches, chip conveyor interface, and external air hose and gun. The machine features the FANUC OiTF+ control which include many value added features. Available in TALENT 42 and 51 variants.

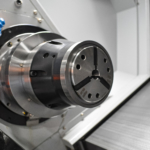

- A2-5 16C collet-ready spindle (TALENT 42)

- A2-6 20C collet-ready spindle (TALENT 51)

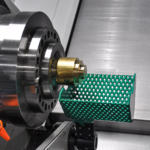

- BMT 45 live tooling 12-station with 1⁄2 Index capability

- Central grease lubrication (manual)

- Foot switch main spindle chuck/collet – open/close

- Foot switch sub-spindle chuck/collet – open/close

- Three color stack light

- Headwall coolant (main & sub-spindle)

- Bar feed interface

- Chip conveyor interface

Powered by FANUC OiTF Plus

- Pendent-mounted Full Control

- 10.4” LCD Display

- Graphic Display

- Embedded Ethernet

- RS-232C Communication Ports

- PCMCIA and USB Ports

- Program Resolution .0001” (.001mm)

- Tool Offset Capability .0001” (.001mm)

- Tool Offsets with Geometry/Wear (99)

- Absolute Encoders

- Inch/Metric Selection by G-Code

- Part Program Storage 512KB

- Actual Cutting Speed and T-Code Display