|

|

TALENT TT 42 |

TALENT TT 51 |

|

Spindle Nose |

A2-5 |

A2-6 |

|

Power Rating / Spindle Speed (max) |

14.75 HP

11 kW / 5000 m-1 |

14.75 HP

11 kW / 5000 m-1 |

|

Max. Machining Length |

17.13 in

435 mm |

16.1 in

409 mm |

|

Max. Machining Diameter |

8.58 in

218 mm |

8.58 in

218 mm |

|

Max. Bar Capacity |

1.65 in

42 mm |

2.05 in

52 mm |

|

Number of turret stations (BMT45) |

16 station |

16 station |

|

Machine Weight |

16,535 lbs

7,500 kg |

16,535 lbs

7,500 kg |

|

Machine Dimensions (L x D x H) |

148 x 80 x 79.45 in

3759 x 2032 x 2018.03 mm |

148 x 80 x 79.45 in

3759 x 2032 x 2018.03 mm |

The cycle time reducer

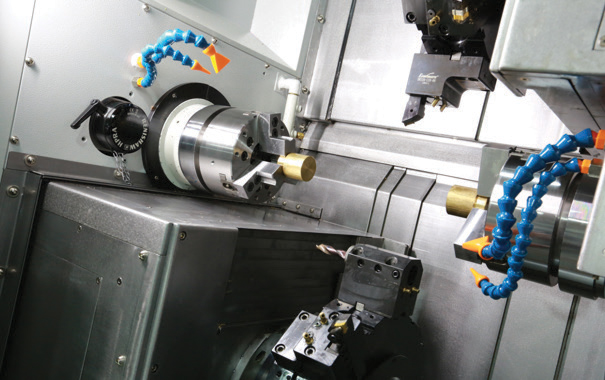

Obtain optimum throughput for your production facility or job shop. The Talent TT Series turning machines provide ultimate flexibility, capability, functionality and maximum productivity all with minimal operator intervention. The machine is configured with 8 axis for the most demanding production requirements. Either turret is capable of working on either spindle, independently or simultaneously, without limitations for maximum part processing flexibility to reduce cycle times. Additionally, should the need arise either the secondary spindle or the lower turret can be used as a tailstock for added functionality.

Best-in-class features and options

- Finish parts complete in one machine – less parts handling

- Reduced cycle times – two tools in the cut simultaneously

- Reduced work in process

- Reduced lead time for lean manufacturing and JIT delivery

- High volume production – long run batches or dedicated production of simple to complex components

- Wide range of process applications

- Easier processing of part families and less setups due to the large number of available tool stations and configurations

- Reduced setup time with the use of BMT industry standard tooling with very high repeatability

- Compact design requires less floor space than most competitors in its class

- Reduced labor costs – one operator can run multiple machines

- Full Y axis capability on upper turret

- Both turrets can work on either or both spindles simultaneously.

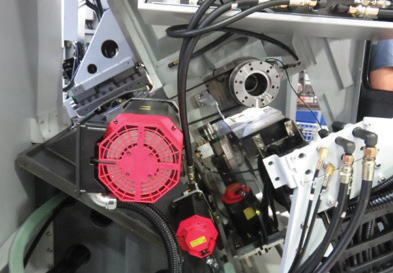

- Hand scrapped structural joints to increase contact

- Heavy duty linear guideways and ball screws

- Wide variety of spindle tooling is available

FANUC 0iTF Dual-Path Split Screen Control

The Hardinge TT Series of multi-tasking turning centers features a custom designed CNC with dual processing power, speed and ease of operation to get the most out of your turning center. Experienced CNC users will appreciate fast machining cycles with the OiTF controls powerful 64 Bit dual processing capabilities.

Program both the main and secondary spindles for simultaneous machining — synchronized spindles assure smooth part transfer. C-Axis and spindle orient on both spindles accommodate complex machining. Synchronization of the tapping axis and spindle rotation allows the use of rigidly-mounted taps.

A split-screen 15” LCD display is helpful during setup for viewing of positions, distances- to-go, and programs all on a single screen. The background programming feature allows you to load the next program “off-line” while the machine is busing producing parts.

A simulated, graphic toolpath display verifies correctness of each step of the operator’s program.

Full complement of standard features for maximum performance — very few options needed.